Scott Generating Set Restoration (Continues)

+9

Robotstar5

nickh

RichieR

oldgit

Andrew1971

maryalice

blue cat

StuartTurnerSteve

Woodsman

13 posters

Page 11 of 13

Page 11 of 13 •  1, 2, 3 ... 10, 11, 12, 13

1, 2, 3 ... 10, 11, 12, 13

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Thanks for the information. I have also been trying to ascertain what would be a good replacement and have found two companies web sites which discuss the capacitance values and other variables which need to be considered. One is the Magneto Guys site, who provide a full detailed explanation of the condenser theory in magnetos and the variables that need to be considered including dV/dt ratings. The other is Brightspark Magnetos who market various forms of their own developed replacement device called EasyCap Condensers. These are designed as bespoke replacement for some magnetos or they supply a universal type which is deigned to be adapted to fit any magneto as required. In the case of the universal type they provide them in two values 0.15uF and 0.22uF. They suggest if you're not aware of which to use, then as a rule of thumb, is to use 0.15uF for rotating coil magnetos and 0.22F for rotating-magnets, flywheel magnetos and for battery coil systems.

So based on your comments and the information from these sites, I will be looking at 0.22uF as the basic value but will also bare in mind the other factors which also impact on selection.

Neil.

So based on your comments and the information from these sites, I will be looking at 0.22uF as the basic value but will also bare in mind the other factors which also impact on selection.

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

There is also another well used condenser and that is the one used on pre electronic ignition system of cars.

https://www.bing.com/images/search?view=detailV2&ccid=PO674ZCM&id=3786030800516AE9DD42633DD70F27A44D4CEDA3&thid=OIP.PO674ZCMkcJXJAmmA6KZNwHaE6&mediaurl=https%3a%2f%2fimages-na.ssl-images-amazon.com%2fimages%2fI%2f71k1Y5d3koL._AC_SL1500_.jpg&cdnurl=https%3a%2f%2fth.bing.com%2fth%2fid%2fR.3ceebbe1908c91c2572409a603a29937%3frik%3do%252b1MTaQnD9c9Yw%26pid%3dImgRaw%26r%3d0&exph=994&expw=1500&q=old+style+car+condensers&simid=608013382017039172&FORM=IRPRST&ck=378FF1E28F0FC4B3470B9B8DF23A1D76&selectedIndex=30&ajaxhist=0&ajaxserp=0

https://www.bing.com/images/search?view=detailV2&ccid=PO674ZCM&id=3786030800516AE9DD42633DD70F27A44D4CEDA3&thid=OIP.PO674ZCMkcJXJAmmA6KZNwHaE6&mediaurl=https%3a%2f%2fimages-na.ssl-images-amazon.com%2fimages%2fI%2f71k1Y5d3koL._AC_SL1500_.jpg&cdnurl=https%3a%2f%2fth.bing.com%2fth%2fid%2fR.3ceebbe1908c91c2572409a603a29937%3frik%3do%252b1MTaQnD9c9Yw%26pid%3dImgRaw%26r%3d0&exph=994&expw=1500&q=old+style+car+condensers&simid=608013382017039172&FORM=IRPRST&ck=378FF1E28F0FC4B3470B9B8DF23A1D76&selectedIndex=30&ajaxhist=0&ajaxserp=0

maryalice- Life Member

- Posts : 1310

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

neil (LE) wrote: (snip) I understand the PAB does use the loop scavenge principle, some say they were the first manufacturer to do so. Certainly they pre-dated other companies such as MZ who claimed it as their own. I must admit I will have to look up the Walter Kaden expansion chamber, as I am not familiar with it.

Hopefully more to come...….

Neil.

This might interest you:-

As the stationary engine collecting son of a Scott motorcycle enthusiast, I have always sought to add examples of the marque to my collection and was recently lucky enough to acquire one of the ‘PA’ types which were used to power the wartime Bofors anti-aircraft gun. At first sight one might doubt that this was a Scott design at all - it is after all air cooled, petroil lubricated and has a flat (well, slightly conical) piston crown. However, the connecting rod has that familiar thin oval section and the ‘style’ of the main castings with their various cover plates is somehow reminiscent of the three cylinder motorcycle engines. But what of that flat top piston – surely loop scavenging was an entirely alien concept to Scott until the much later Swift project?

Investigation of the cylinder porting revealed it was indeed a loop scavenged design, with not only classic paired Schneurle type transfer ports at approximately 90 degrees to the exhaust port, but also a small ‘boost’ port at 180 degrees (i.e. opposite the exhaust). This arrangement is widely supposed to have made its debut in 1957 on Walter Kaaden’s successful 125cc MZ racing machines (e.g. Cesare Bossaglia ‘Two-Stroke High Performance Engine Design & Tuning’ and Graham Bell ‘Two-Stroke Performance Tuning’), though the typically thorough Phil Irving (‘Two-Stroke Power Units’) points out that a similar system was patented by Zundapp in 1933, primarily in an attempt to circumvent the Schneurle patents, but not pursued for production until much later. Whatever its precise origins, the appearance of such a boost port in a production engine of the 1940’s can be considered pretty ‘cutting edge’.

Some digging on the internet turned up GB patent number 512980 ‘Improvements in or relating to the scavenging of the cylinders of two-stroke-cycle internal combustion engines’ granted to Scott Motors Saltaire Ltd. and William Cull in 1939 and describing precisely this arrangement of ports. Interestingly the design is illustrated on an engine bearing a distinct resemblance to the Cyc-Auto (it has the characteristic inlet passage running down the side of the cylinder from a high mounted carb). I’m not sufficiently familiar with the various Cyc-Auto engines to be able to say whether the third transfer port was used on production models – but if it was, then that least regarded of Scotts may just be one of the most technically advanced!

nickh- Expert

- Posts : 56

Join date : 2019-04-14

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Thank you for your interesting post. You have provided a lot of information about these engines that is new to me which I will need to record so I don't loose it.

You say that "as a son of a Scott motorcycling enthusiast" you have recently acquired a Scott P.A. As such do you know any of the history of the unit, is it recently discovered engine or an existing enthusiast's unit which has been moved on? I ask for two reasons really, first I'm interested in understanding how many of these engines and the complete sets have survived. In 1984, Phillip Galimore, who I believe was the Stationary Engine magazine marque specialist for Scott engines, suggested that he was only aware of ten surviving examples. I wonder how many more have surfaced in the intervening years? I imagine quite a few but I'm not aware of any records being maintained of known surviving examples. The second reason is with regard to how you became an owner, through your father being a Scott enthusiast. My complete Jowett generator set was originally acquired by an ardent Jowett car collector and when he discovered the generating set he bought it and kept it purely as a curio of the Jowett brand, to display alongside his car collection. After he passed on his family didn't want it, so an engine enthusiast took it in, to stop it being scrapped. I was just lucky enough to be directed to it and was able to purchase it for renovation and display.

Neil.

You say that "as a son of a Scott motorcycling enthusiast" you have recently acquired a Scott P.A. As such do you know any of the history of the unit, is it recently discovered engine or an existing enthusiast's unit which has been moved on? I ask for two reasons really, first I'm interested in understanding how many of these engines and the complete sets have survived. In 1984, Phillip Galimore, who I believe was the Stationary Engine magazine marque specialist for Scott engines, suggested that he was only aware of ten surviving examples. I wonder how many more have surfaced in the intervening years? I imagine quite a few but I'm not aware of any records being maintained of known surviving examples. The second reason is with regard to how you became an owner, through your father being a Scott enthusiast. My complete Jowett generator set was originally acquired by an ardent Jowett car collector and when he discovered the generating set he bought it and kept it purely as a curio of the Jowett brand, to display alongside his car collection. After he passed on his family didn't want it, so an engine enthusiast took it in, to stop it being scrapped. I was just lucky enough to be directed to it and was able to purchase it for renovation and display.

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Can't quite remember when I wrote that piece, but it's certainly not 'recently' any more!

I bought it through an advert in SEM and I think it had been lurking in the sellers shed for some years. I also aquired another (free) in very rough and partially dismantled condition which has provided parts for at least three others, so there are a few around. I have only seen one complete set though, which was on a trade stall at one of the rallies down south (Kingsfold, Laughton or ....?) some years ago.

I bought it through an advert in SEM and I think it had been lurking in the sellers shed for some years. I also aquired another (free) in very rough and partially dismantled condition which has provided parts for at least three others, so there are a few around. I have only seen one complete set though, which was on a trade stall at one of the rallies down south (Kingsfold, Laughton or ....?) some years ago.

nickh- Expert

- Posts : 56

Join date : 2019-04-14

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Nick,

Nice to see you joining in.

Maryalice

Nice to see you joining in.

Maryalice

maryalice- Life Member

- Posts : 1310

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Nick,

Thank you for the information, I wonder if there is a register with details of known examples. If there is, I would be interested to see what information was available.

From what you say, I assume you have more than one engine or have at least assisted others with their restorations, all of which indicates there are more out there. I always keep an eye out for any of these units, especially the complete sets. I would be interested to know where the complete set you mentioned ended up, especially as that is in my neck of the woods!

Neil.

Thank you for the information, I wonder if there is a register with details of known examples. If there is, I would be interested to see what information was available.

From what you say, I assume you have more than one engine or have at least assisted others with their restorations, all of which indicates there are more out there. I always keep an eye out for any of these units, especially the complete sets. I would be interested to know where the complete set you mentioned ended up, especially as that is in my neck of the woods!

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Not much left of the second unit now but as you surmise, it hopefully helped others to get their engines up and running.

Don't know if the complete unit sold, think dealer wanted something like £350.

Don't know if the complete unit sold, think dealer wanted something like £350.

nickh- Expert

- Posts : 56

Join date : 2019-04-14

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

More Magneto Updates

Having decided to replace the capacitors (condensers) on the two "good" magnetos, I have purchased some universal EasyCap condensers from Brightspark magnetos. In the end I decided to acquire both values available, 0.15uF and 0.22uF to allow for testing, to identify if there is any appreciable difference between them in use. These components will be cut down to fit in the old plastic cases.

EasyCap Universal 0.15uF replacement Condenser being tested at (158nF) 0.16uF.

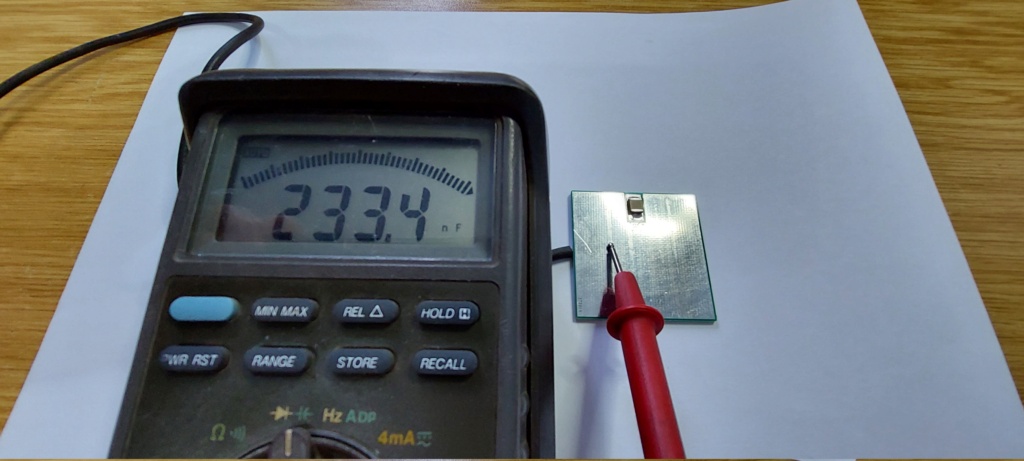

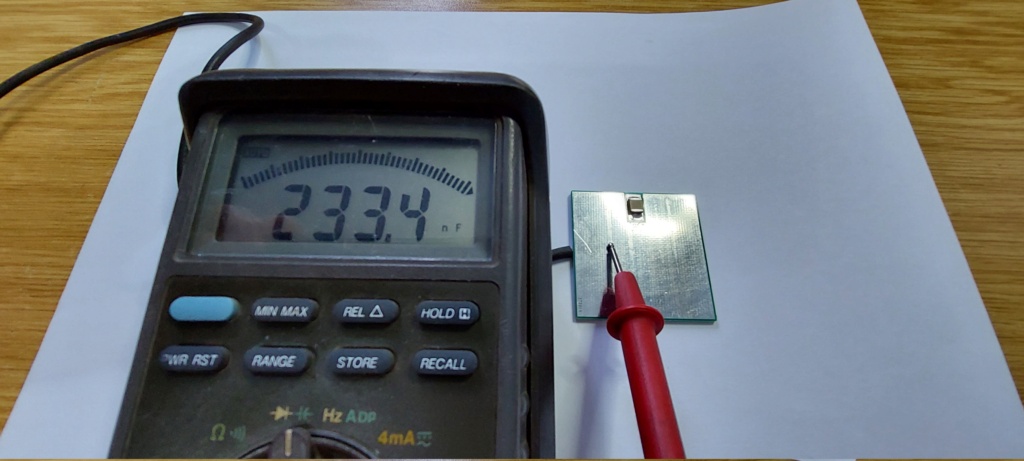

With the 0.22uF unit testing at (233nF) 0.23uF.

My latest spare magneto has arrived and as thought, it is the opposite rotation from the others. Unfortunately it has also proven to be open circuit on the secondary coil however out of curiosity I tested it to see if there was any life in it using a drill to spin it over.

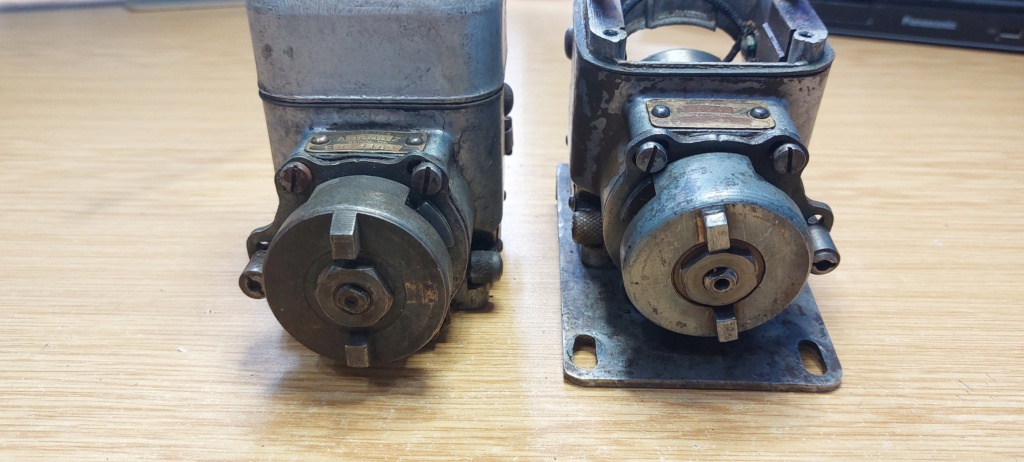

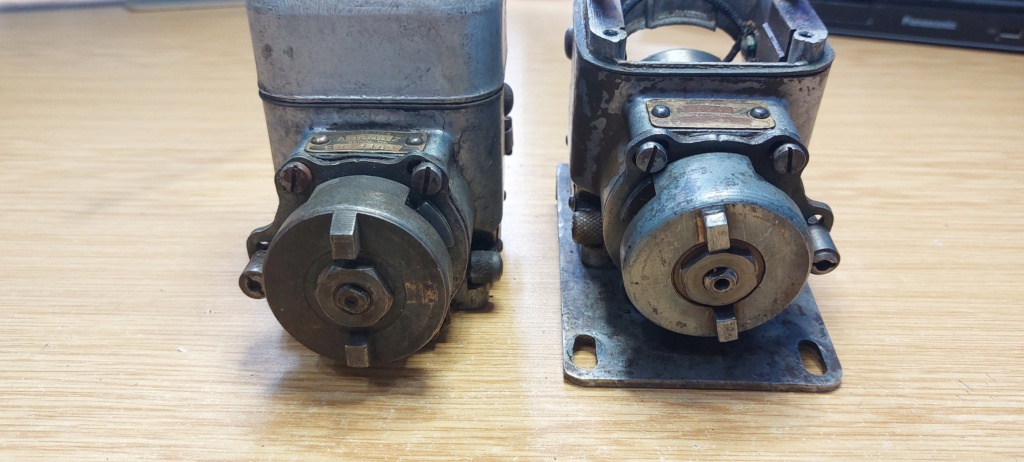

New unit on the left. The position of the trip mechanism identifying that it rotates in the opposite direction.

Condition of the points unit with an old style condenser fitted and an interesting felt insulation pad instead of the mica strip.

Although secondary coil is reading open circuit, it is still able to produce a reasonable spark.

Producing sparks by turning it over by hand against the trip mechanism. How long would it continue to work, as it must be arcing internally to be able to produce a spark, is uncertain.

Further progress will follow, hopefully.....

Neil

Having decided to replace the capacitors (condensers) on the two "good" magnetos, I have purchased some universal EasyCap condensers from Brightspark magnetos. In the end I decided to acquire both values available, 0.15uF and 0.22uF to allow for testing, to identify if there is any appreciable difference between them in use. These components will be cut down to fit in the old plastic cases.

EasyCap Universal 0.15uF replacement Condenser being tested at (158nF) 0.16uF.

With the 0.22uF unit testing at (233nF) 0.23uF.

My latest spare magneto has arrived and as thought, it is the opposite rotation from the others. Unfortunately it has also proven to be open circuit on the secondary coil however out of curiosity I tested it to see if there was any life in it using a drill to spin it over.

New unit on the left. The position of the trip mechanism identifying that it rotates in the opposite direction.

Condition of the points unit with an old style condenser fitted and an interesting felt insulation pad instead of the mica strip.

Although secondary coil is reading open circuit, it is still able to produce a reasonable spark.

Producing sparks by turning it over by hand against the trip mechanism. How long would it continue to work, as it must be arcing internally to be able to produce a spark, is uncertain.

Further progress will follow, hopefully.....

Neil

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

If it's producing a spark then it jumping the break and causing an internal spark which will increase the gap until total failure.

maryalice- Life Member

- Posts : 1310

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Yes, unfortunately that is what occurred with the previous magneto. While I was testing the engine, it finally failed as it eroded the wire at the break point and the spark was unable to jump the gap. It is now, as you say, a total and permanent failure. I'm certain this one will eventually do the same.

Neil

Neil

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

https://www.ebay.co.uk/itm/275362513175

nickh- Expert

- Posts : 56

Join date : 2019-04-14

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Thanks for that, somehow I hadn't seen this one when I was searching. I will watch it and see if it gets any attention.

Neil.

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Highs and Lows of an Engine Restoration and a Cautionary Tale!

The Highs. Some of you may have read my post in the Stationary Engine Section under the Petter A Series 11 - Wico A Magneto Issue, where I commented on the fact that following the rebuild of my magneto, using the best selection of parts from my spare units, I had successfully run the Scott again. I felt I had at last turned the corner and could look forward to being able to complete the restoration. Unfortunately the feeling was once again, going to be short lived!

The Lows. The day following the successful run of the engine I was in the garage considering how I should proceed when I happened to turn the engine over with my hand on the flywheel and noticed much more resistance than usual. To reassure myself I removed the plug, as I was rather hopefully assuming the compression had increased following the run and that was causing the issue. Unfortunately with the plug removed there was still a distinct binding of the engine as it was being rotated.

My initial concern was the engine had nipped up during the test run. I checked I had been using two stroke fuel and not neat petrol, by looking at the remaining fuel I could confirm it was a two stroke mix. My next thought was the crank had gone out of alignment again after having to have it trued up previously. I would have been very worried if I had continued to use starter spray, as this could have resulted in a bent rod or the crank alignment issue but I hadn't used the spray since the initial start up attempts. Recent starting attempts had been assisted by the use of fuel introduced directly into the cylinder. This technique was to have an repercussions later on.

Without understanding where or why the engine was binding, I felt I had no option other than to strip the engine down once more, in an attempt to identify the root cause. It was therefore with some trepidation that I removed all the cowling again to be able to separate the cylinder and head from the crankcase, to reveal the piston. Initial examination didn't identify anything obviously amiss with either the piston or bore but resistance could still be felt when turning the engine over by hand, although it seem to feel slightly better than it had been. Further assessment was required therefore in an attempt to understand how bad the situation was decided to see if the engine would fire up for a couple of cycles using priming fuel through the spark plug hole. The piston was refitted to the conrod and the cylinder and head bolted back onto the crankcase, nothing else was assembled, it was just the bare cylinder, without carburettor or exhaust.

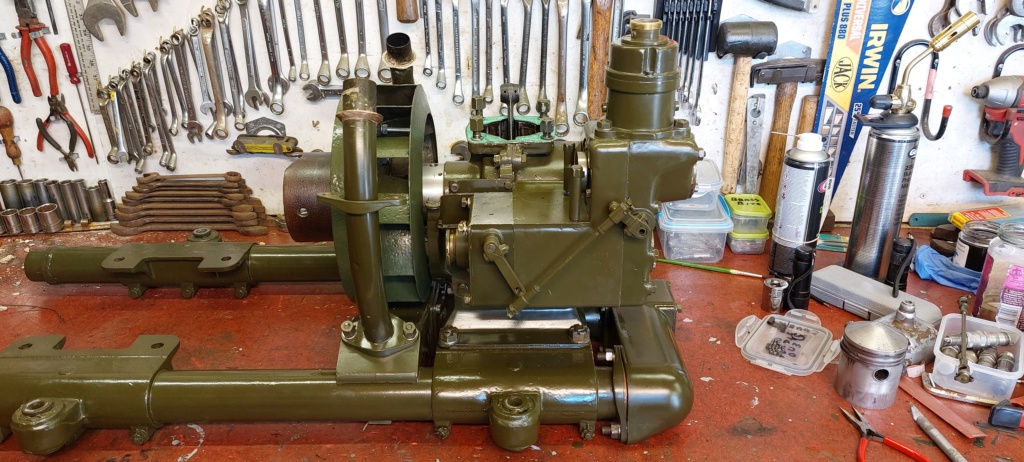

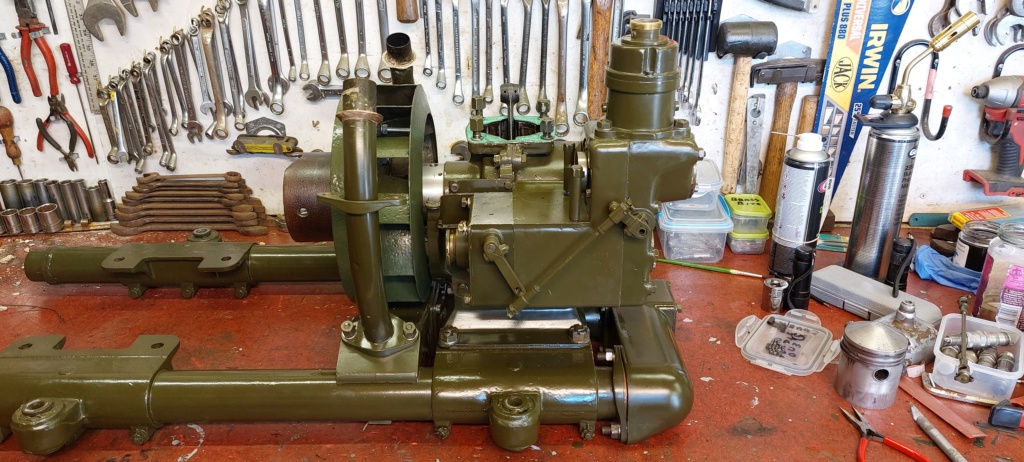

Engine stripped down once more, in an attempt to identify the cause of the engine binding.

Now for the cautionary tale. All I intended to achieve through this test was to see if the engine would fire up enough to turn over for a couple of cycles without seizing up or without sounding mechanically damaged. Not having a carburettor fitted, the only way to prime the engine was to use the plug hole which would allow the engine to bark up and turn over just enough to hopefully discern any issues, always assuming it would turn over at all.

What actually happened took me totally by surprise. When I pulled started the engine not only did it fire up but it immediately started to run up, uncontrollably running away and gaining speed up to and beyond its normal rated revs. There was no way to stop the engine, without the carburettor being fitted, I couldn't use the throttle to control the engine and due to the use of a screened ignition lead, it was not possible to pull the plug lead off. Even if this action could have damaged the magneto, in this situation I would have done so. Although I could have blocked the carburettor air intake passage, even if I thought about it quick enough, this would have meant getting very close to an engine that was in the process of seriously and uncontrollably running away. After what seemed like an eternity, much to my relief, the engine started to slow down and finally stopped, after about 15 - 20 seconds. This may not seem like a long time but when an engine is running away uncontrollably at an estimated speed of 3500 - 4000 rpm, with no exhaust system fitted, it can be very disconcerting to say the least. I seriously worried about the engine overstressing and failing mechanically, causing major damage or even injury. On reflection it is testament to the build quality and balance of the engine that it could run away well above its rated speed while sat on the bench without even moving, which could have been disastrous.

I've heard of diesel engines running away by consuming their own sump oil and I suppose this event was the two stroke petrol engine equivalent. I can only assume the regular priming of the engine to aid starting had resulted in the accumulation of fuel within the crankcase. With no carburettor fitted there was a wide open air intake with the crankcase fuel being pumped up into the cylinder, allowing the engine to run uncontrollably until the crankcase was emptied of fuel.

Lessons learnt from this event, is the practise of putting neat fuel into an engine to assess if it is viable needs to be carefully considered. In most cases it would not be an issue with a four stoke engine but two strokes present potential to cause a dangerous situation to exist. I have been working on two and four stroke bikes and engines for fifty years and have never had an issue like this before. Having now experience this situation I am going to be exceedingly cautious in the future about dosing a two stroke engine to test it, if there isn't a carburettor fitted which can control the air intake.

Now for some good news. Following this event, once I got my breath back, I decided to check the engine over and was initially extremely worried that the flywheel was found to be loose. Obviously if this had come off, it would have crashed across the garage which really doesn't bear thinking about. What I don't know is if it became loose due to the engine running as it did, or was it loose before, due to it being removed and replaced a number of times and hadn't been tightened up fully. Either way, once the nut was fully secured, the engine was found to turn over really smoothly and now feels as good as it ever has. If this was the cause of the problems of it binding all along, with the flywheel being out of alignment I will never know. What I do know, is the engine now freely turns over, starts easily and runs well.

Having now determined adrenaline is brown and smelly, I can now continue with the set rebuild....

Neil.

The Highs. Some of you may have read my post in the Stationary Engine Section under the Petter A Series 11 - Wico A Magneto Issue, where I commented on the fact that following the rebuild of my magneto, using the best selection of parts from my spare units, I had successfully run the Scott again. I felt I had at last turned the corner and could look forward to being able to complete the restoration. Unfortunately the feeling was once again, going to be short lived!

The Lows. The day following the successful run of the engine I was in the garage considering how I should proceed when I happened to turn the engine over with my hand on the flywheel and noticed much more resistance than usual. To reassure myself I removed the plug, as I was rather hopefully assuming the compression had increased following the run and that was causing the issue. Unfortunately with the plug removed there was still a distinct binding of the engine as it was being rotated.

My initial concern was the engine had nipped up during the test run. I checked I had been using two stroke fuel and not neat petrol, by looking at the remaining fuel I could confirm it was a two stroke mix. My next thought was the crank had gone out of alignment again after having to have it trued up previously. I would have been very worried if I had continued to use starter spray, as this could have resulted in a bent rod or the crank alignment issue but I hadn't used the spray since the initial start up attempts. Recent starting attempts had been assisted by the use of fuel introduced directly into the cylinder. This technique was to have an repercussions later on.

Without understanding where or why the engine was binding, I felt I had no option other than to strip the engine down once more, in an attempt to identify the root cause. It was therefore with some trepidation that I removed all the cowling again to be able to separate the cylinder and head from the crankcase, to reveal the piston. Initial examination didn't identify anything obviously amiss with either the piston or bore but resistance could still be felt when turning the engine over by hand, although it seem to feel slightly better than it had been. Further assessment was required therefore in an attempt to understand how bad the situation was decided to see if the engine would fire up for a couple of cycles using priming fuel through the spark plug hole. The piston was refitted to the conrod and the cylinder and head bolted back onto the crankcase, nothing else was assembled, it was just the bare cylinder, without carburettor or exhaust.

Engine stripped down once more, in an attempt to identify the cause of the engine binding.

Now for the cautionary tale. All I intended to achieve through this test was to see if the engine would fire up enough to turn over for a couple of cycles without seizing up or without sounding mechanically damaged. Not having a carburettor fitted, the only way to prime the engine was to use the plug hole which would allow the engine to bark up and turn over just enough to hopefully discern any issues, always assuming it would turn over at all.

What actually happened took me totally by surprise. When I pulled started the engine not only did it fire up but it immediately started to run up, uncontrollably running away and gaining speed up to and beyond its normal rated revs. There was no way to stop the engine, without the carburettor being fitted, I couldn't use the throttle to control the engine and due to the use of a screened ignition lead, it was not possible to pull the plug lead off. Even if this action could have damaged the magneto, in this situation I would have done so. Although I could have blocked the carburettor air intake passage, even if I thought about it quick enough, this would have meant getting very close to an engine that was in the process of seriously and uncontrollably running away. After what seemed like an eternity, much to my relief, the engine started to slow down and finally stopped, after about 15 - 20 seconds. This may not seem like a long time but when an engine is running away uncontrollably at an estimated speed of 3500 - 4000 rpm, with no exhaust system fitted, it can be very disconcerting to say the least. I seriously worried about the engine overstressing and failing mechanically, causing major damage or even injury. On reflection it is testament to the build quality and balance of the engine that it could run away well above its rated speed while sat on the bench without even moving, which could have been disastrous.

I've heard of diesel engines running away by consuming their own sump oil and I suppose this event was the two stroke petrol engine equivalent. I can only assume the regular priming of the engine to aid starting had resulted in the accumulation of fuel within the crankcase. With no carburettor fitted there was a wide open air intake with the crankcase fuel being pumped up into the cylinder, allowing the engine to run uncontrollably until the crankcase was emptied of fuel.

Lessons learnt from this event, is the practise of putting neat fuel into an engine to assess if it is viable needs to be carefully considered. In most cases it would not be an issue with a four stoke engine but two strokes present potential to cause a dangerous situation to exist. I have been working on two and four stroke bikes and engines for fifty years and have never had an issue like this before. Having now experience this situation I am going to be exceedingly cautious in the future about dosing a two stroke engine to test it, if there isn't a carburettor fitted which can control the air intake.

Now for some good news. Following this event, once I got my breath back, I decided to check the engine over and was initially extremely worried that the flywheel was found to be loose. Obviously if this had come off, it would have crashed across the garage which really doesn't bear thinking about. What I don't know is if it became loose due to the engine running as it did, or was it loose before, due to it being removed and replaced a number of times and hadn't been tightened up fully. Either way, once the nut was fully secured, the engine was found to turn over really smoothly and now feels as good as it ever has. If this was the cause of the problems of it binding all along, with the flywheel being out of alignment I will never know. What I do know, is the engine now freely turns over, starts easily and runs well.

Having now determined adrenaline is brown and smelly, I can now continue with the set rebuild....

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Phew !! Thanks for posting - a lesson for us all.

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2815

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Following my near disaster, I thought I would share some better news. In my previous post, in the final sentence, I said the engine had been reassembled and had been successfully started. In the past when this had been achieved, I found it was not so on the following day. Normally the engine would refuse to start, without numerous attempts and lots of coaxing. This time however, I was relieved to find that with a single pull the engine fired up and continued to run very well and I was able to repeat the starting process a number of times without effort. I did need to prime the engine but I'm hopeful that this may not be necessary, once I'm able to use the proper starting handle and operate the choke and mixture controls correctly. The engine has been reunited with the original but serviced magneto, which was on it when the engine ran up to high speeds, so seems to be working well, but I'm still using the substitute carburettor from the Jowett. I will change back to the original item at some point, to assess how it compares with the one currently fitted.

Neil.

Scott engine having been reassembled, happily and smoothly running on a single float bowl of fuel. Hopefully I will not need to take it apart again!

Neil.

Scott engine having been reassembled, happily and smoothly running on a single float bowl of fuel. Hopefully I will not need to take it apart again!

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Great job Neil. I bet Carbon Monoxide / Dioxide levels got a bit high - trust you had the door open.

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2815

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Hi thanks. Yes both the main door and the side door of the garage were open, to help blow it through. Also I exited stage left immediately and stayed outside for some time, once I had finished videoing it running. In fact you are able to see plumes of exhaust fumes billowing out of the doors, which certainly reminds you not to enter!

You can never be too careful.

Neil.

You can never be too careful.

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Great stuff! Glad your sorted, always an anxious moment a first fire up but it sounds good!

Alan

Alan

Alanengine- A credit to the forum

- Posts : 461

Join date : 2020-11-21

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Related your comment to my 'live-in carer' - sadly we don't have an emoticon for "Wife giggling hysterically"neil (LE) wrote:

Having now determined adrenaline is brown and smelly, I can now continue with the set rebuild....

Neil.

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2815

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

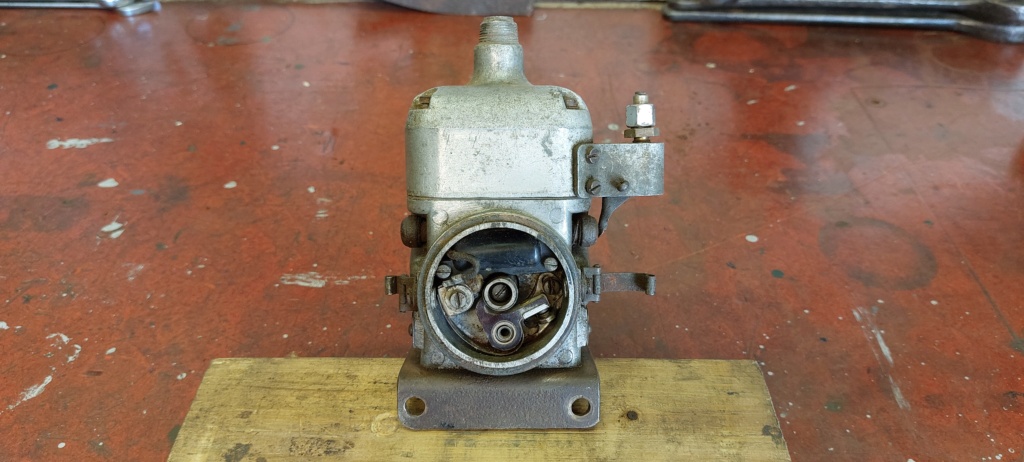

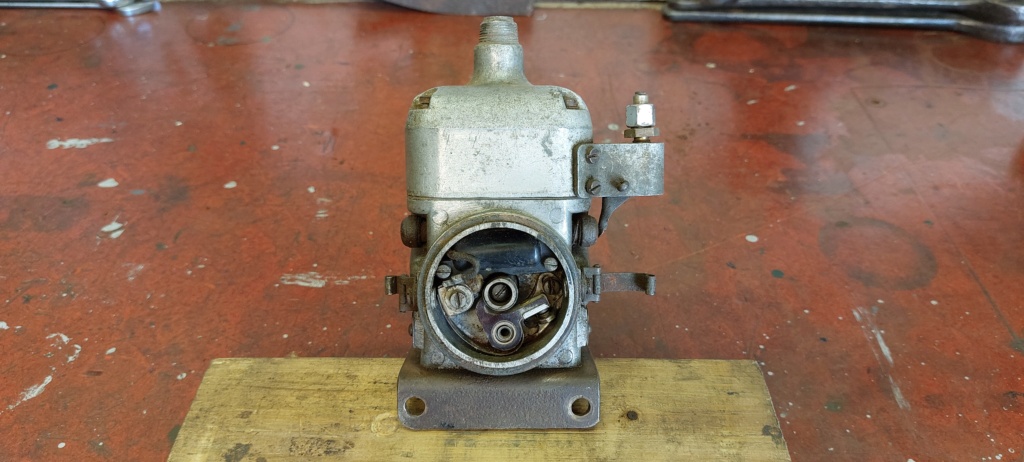

Update for nickh and for the interest of others. I watched the the ebay auction for the magneto you bought to my attention. I also got in touch with the vendor to confirm that there was actually a coil and a points unit fitted. He was helpful enough to send me some additional pictures to show them in place. I was fortunate enough to win the auction at the opening figure, as the only bidder.

The main reason I considered this was something worth bidding on, was the fact it was a fully screened type, including the remote cut-out switch, only fitted to radio frequency interference suppressed units, as used on the Scott generators. This type is not often available, as they were not that common in their day, less so now.

I have now received the magneto and it is all there and even better, the coil actually tests out as working which was actually quite a surprise and a bonus!

Edit:- I have now been able to prove the magneto function. By turning the magneto over against the impulse start mechanism I am able to produce a strong blue spark from an H.T. lead to the case. A good result from a risk purchase.

Thanks,

Neil.

New magneto as received. Note the R.F.I. suppression remote stop assembly.

Points cover removed, revealing a complete unit, apart from the points fixing screw.

The coil H.T. stud, missing its contact spring. Hopefully easily repaired.

H.T. secondary coil resistance reading as 5.48K ohm, which indicates a viable unit.

The main reason I considered this was something worth bidding on, was the fact it was a fully screened type, including the remote cut-out switch, only fitted to radio frequency interference suppressed units, as used on the Scott generators. This type is not often available, as they were not that common in their day, less so now.

I have now received the magneto and it is all there and even better, the coil actually tests out as working which was actually quite a surprise and a bonus!

Edit:- I have now been able to prove the magneto function. By turning the magneto over against the impulse start mechanism I am able to produce a strong blue spark from an H.T. lead to the case. A good result from a risk purchase.

Thanks,

Neil.

New magneto as received. Note the R.F.I. suppression remote stop assembly.

Points cover removed, revealing a complete unit, apart from the points fixing screw.

The coil H.T. stud, missing its contact spring. Hopefully easily repaired.

H.T. secondary coil resistance reading as 5.48K ohm, which indicates a viable unit.

Last edited by neil (LE) on Fri Jul 08 2022, 17:32; edited 1 time in total (Reason for editing : Edit added.)

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Well done Neil good to get a result and to have it working is the icing on the cake!

I'd be a bit cautious about testing for big sparks though (anything bigger than a normal plug gap) as it can encourage internal breakdown of insulation.

Alan

I'd be a bit cautious about testing for big sparks though (anything bigger than a normal plug gap) as it can encourage internal breakdown of insulation.

Alan

Alanengine- A credit to the forum

- Posts : 461

Join date : 2020-11-21

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

Thanks Alan. Sorry when I said big fat spark, I meant a good blue spark at the normal gap, rather than a weak yellow spark, often associated with failing coils or condensers. I was getting a little carried away with my own enthusiasm for my purchase. I'm still amazed that it has turned up, as described and is actually in good working order. I intend to keep it that way, so I will not be over stressing it, by playing "jump the gap" games!

One happy man, cheers,

Neil.

One happy man, cheers,

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

No probs - didn't want you to muck up your new mag!

Alan

Alan

Alanengine- A credit to the forum

- Posts : 461

Join date : 2020-11-21

Re: Scott Generating Set Restoration (Continues)

Re: Scott Generating Set Restoration (Continues)

neil (LE) wrote:Update for nickh and for the interest of others. I watched the the ebay auction for the magneto you bought to my attention........

.........The main reason I considered this was something worth bidding on, was the fact it was a fully screened type, including the remote cut-out switch, only fitted to radio frequency interference suppressed units, as used on the Scott generators. This type is not often available, as they were not that common in their day, less so now.

It was the base plate which caught my eye - PAB specific type isn't it?

nickh- Expert

- Posts : 56

Join date : 2019-04-14

Page 11 of 13 •  1, 2, 3 ... 10, 11, 12, 13

1, 2, 3 ... 10, 11, 12, 13

Similar topics

Similar topics» Scott PAB Restoration

» Kubota diesel KND3

» Trolley for Villiers Mk15 wooden toolbox new pics 5-9-2016

» Petter generating set - might turn into a project

» Douglas FT35 generating set

» Kubota diesel KND3

» Trolley for Villiers Mk15 wooden toolbox new pics 5-9-2016

» Petter generating set - might turn into a project

» Douglas FT35 generating set

Page 11 of 13

Permissions in this forum:

You cannot reply to topics in this forum