Nutgone's Tarpen

+6

Statman

Ianhw77k

matt86

Abes

pauldg

nutgone

10 posters

Page 1 of 4

Page 1 of 4 • 1, 2, 3, 4

Nutgone's Tarpen

Nutgone's Tarpen

OK, so lets start from the beginning, very briefly.....

My dad bought my brother & me this engine when we were about 7 years old, it was a runner from day one & saw many rallies with us through the years, eventually kinda becoming my engine, I lightly restored it in the early 90s, replacing the (broken) fibre shaft coupling, renewing the fan-belt, de-coking & giving it a fresh coat of British Racing Green.

She then saw a few more rallies until, eventually, my brother & I hit our late teens & started to lose interest. When we were 19 my parents sold the house. The engines, Tarpen included, went to live at my sister's place. She later moved house & all the engines were relegated to a corner of the garden, under tarpaulin.

Fast forward to 2012 & after a couple of years of me showing my retro car(s) at local rallies & a rediscovered passion for camping, not to mention a couple of kids (not my own, but my nephews) getting interested, we decided it might be "nice" to drag an engine or two out from the tarp & enter a few rallies, it was decided the Tarpen would be the easiest to get going, so out she came & back to my mum & dad's place (where I am currently residing, for my sins). Here she is, or was.......

I decided to clean it up a bit & take the head & barrel off, see what lies beneath......

Back together she went, only to find there was no spark (hardly surprising, really

(hardly surprising, really  )

)

Thing is, she had always been such a reliable engine, we'd never had cause to look inside the flywheel magneto before. First job was getting the crankshaft nut undone, it was so tight I thought it must be a left hander, & thankfully it was! But the flywheel itself was a different matter. We had this engine entered in a few rallies, & although slightly embarrassing I felt it better to actually attend & show something, rather than be a no-show.

After the last event (Wiston Park, in West Sussex) we decided to go all out & get that wheel off. We re-tapped the threads from the rope-start pulley, got some 6mm stud & assembled a puller.

We tightened as far as we dared, & whilst no one was looking I tightened it a bit more , then we hit it with a copper faced mallet...... NOTHING!

, then we hit it with a copper faced mallet...... NOTHING!

We decided to leave it over night, then maybe apply some heat, but whilst out there for a smoke after dinner I decided to give it a proper hit with a solid hammer (give it a proper shock). So I smacked it a couple of times & the puller studs went loose!

I thought I'd broken something (else! ) but looked around & saw it had moved....

) but looked around & saw it had moved....

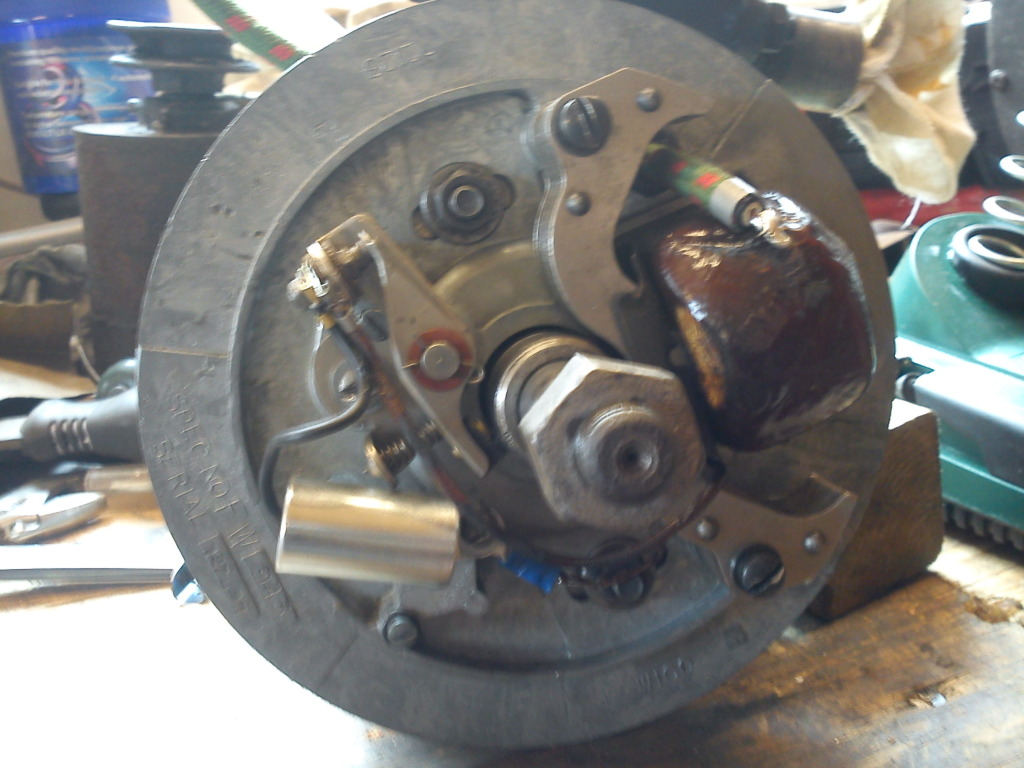

(BTW it was the end of the puller I hit, NOT the flywheel or anything else). The rest was simple, in a matter of minutes the pesky flywheel was off, revealing the mag innards......

Anyway, that's enough for now, I will continue in the next post........

My dad bought my brother & me this engine when we were about 7 years old, it was a runner from day one & saw many rallies with us through the years, eventually kinda becoming my engine, I lightly restored it in the early 90s, replacing the (broken) fibre shaft coupling, renewing the fan-belt, de-coking & giving it a fresh coat of British Racing Green.

She then saw a few more rallies until, eventually, my brother & I hit our late teens & started to lose interest. When we were 19 my parents sold the house. The engines, Tarpen included, went to live at my sister's place. She later moved house & all the engines were relegated to a corner of the garden, under tarpaulin.

Fast forward to 2012 & after a couple of years of me showing my retro car(s) at local rallies & a rediscovered passion for camping, not to mention a couple of kids (not my own, but my nephews) getting interested, we decided it might be "nice" to drag an engine or two out from the tarp & enter a few rallies, it was decided the Tarpen would be the easiest to get going, so out she came & back to my mum & dad's place (where I am currently residing, for my sins). Here she is, or was.......

I decided to clean it up a bit & take the head & barrel off, see what lies beneath......

Back together she went, only to find there was no spark

Thing is, she had always been such a reliable engine, we'd never had cause to look inside the flywheel magneto before. First job was getting the crankshaft nut undone, it was so tight I thought it must be a left hander, & thankfully it was! But the flywheel itself was a different matter. We had this engine entered in a few rallies, & although slightly embarrassing I felt it better to actually attend & show something, rather than be a no-show.

After the last event (Wiston Park, in West Sussex) we decided to go all out & get that wheel off. We re-tapped the threads from the rope-start pulley, got some 6mm stud & assembled a puller.

We tightened as far as we dared, & whilst no one was looking I tightened it a bit more

We decided to leave it over night, then maybe apply some heat, but whilst out there for a smoke after dinner I decided to give it a proper hit with a solid hammer (give it a proper shock). So I smacked it a couple of times & the puller studs went loose!

I thought I'd broken something (else!

(BTW it was the end of the puller I hit, NOT the flywheel or anything else). The rest was simple, in a matter of minutes the pesky flywheel was off, revealing the mag innards......

Anyway, that's enough for now, I will continue in the next post........

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Interesting story, I think we are all a little scared to hit things to hard with a hammer and tend to pussy foot about, sometimes it just has to be done

Keep us updated on your progress.

Stu.

Keep us updated on your progress.

Stu.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

So the idea was simple, get the flywheel off, clean up the mag, re-set the points & get her running again. So why did I go & do this???.....

Seriously, probably within less than an hour I had the engine dismantled into it's large component parts! I don't know exactly what happened, I'm sure my brother wasn't too happy about it, he wanted a working engine, & I know my dad wasn't too happy about it, he wanted a working workshop, without bits of Tarpen all over the place! But I've never been one for pleasing all of the people all of the time, more of a one for pleasing myself whenever it suits me, I suppose

Anyway, there it was. I have been doing a little research into these machines & I thought it would be great to do a really proper restoration on this one, a proper "nut & bolt" job, & do my best to get it looking like it has just been wheeled out of the factory.

For instance, I found out that the engine cowl is supposed to be polished aluminium, almost everything else is supposed to be a light green colour (which I think I've found). My various stripping has uncovered the probability that the wheels & plug socket were almost undoubtedly black, there wasn't a black stripe on the generator (in fact the generator is a motor & was originally completely black, but would have been painted green at the Tarpen factory). The only bit I'm not completely certain about is the handle. I've got a feeling it should be green, like the rest of the machine, but I haven't found any green paint on it yet (although it's one of the last pieces to be stripped & is still waiting it's turn). I'm even wondering if this isn't the original handle???

So, here I am, surrounded by bits of Tarpen, covered in paint stripper, disappearing in a pile of paint strippings & wire wool! I've managed to dismantle most of the bits & bobs, the drive flanges were easier than I expected, the generator came apart quite easily, but there's a pulley, a V belt pulley, from the generator side of the flexible coupling. This powers a little aluminium fan inside the engine cowling. I simply can't get the damn thing off! I tried a puller, only to find out it's made of cast iron & I've broken a couple of bits off it!

I've even managed to get it to the end of the shaft, by using a blow lamp, a few different hammers & lots of swearing, but it refuses to go any further.

I'm now thinking I will drill 3 carefully spaced holes in it & try my harmonic puller (the one pictured on the flywheel). If I have to break the damn pulley than so be it! I've already found an aluminium replacement on eBay for under £20, so it won't be the end of the world.

Right! So, there's much of the story so far. Yesterday I spent the whole day stripping paint, cleaning & degreasing components, here's some pics of a very productive day's work.....

Engine (supposedly a J.A.P. although it bears no marks whatsoever) degreased & ready for some barrel black....

Tank, centre of genny & fan shroud being stripped.....

First few bits stripped.....

Engine blacked & part way through polishing crank cases.....

All the bits I stripped during the day, safely tucked up for the night.......

Chassis cleaned & degreased, paint stripper applied to be left over night (last job).......

Next on my list, I've got to get that damned pulley off (one way or another) in order to get to the other end of the genny casing (& remove the armature from the genny, for safe storage), finish all the stripping (other end of genny, chassis & handle), then it's all the nuts, bolts & fastenings (clean, strip, degrease & generally get moving again), clean & degrease all the bearings (ready for replacing) then it'll be the preparation for painting; all those stripped bits will have to be sanded down, then a quick go over with some P500 wet & dry before application of a good primer.

I think, after all that, I will paint the top coat on all the bits prior to reassembly, then touch-up wherever needs touching up after it's all back together (or is that a really stupid idea??? It's been a while since I've painted an engine, & never to this kind of standard).

All ideas & suggestions welcome. Today will be a nothing day, but I will keep you all posted of any progress as & when it happens.

Seriously, probably within less than an hour I had the engine dismantled into it's large component parts! I don't know exactly what happened, I'm sure my brother wasn't too happy about it, he wanted a working engine, & I know my dad wasn't too happy about it, he wanted a working workshop, without bits of Tarpen all over the place! But I've never been one for pleasing all of the people all of the time, more of a one for pleasing myself whenever it suits me, I suppose

Anyway, there it was. I have been doing a little research into these machines & I thought it would be great to do a really proper restoration on this one, a proper "nut & bolt" job, & do my best to get it looking like it has just been wheeled out of the factory.

For instance, I found out that the engine cowl is supposed to be polished aluminium, almost everything else is supposed to be a light green colour (which I think I've found). My various stripping has uncovered the probability that the wheels & plug socket were almost undoubtedly black, there wasn't a black stripe on the generator (in fact the generator is a motor & was originally completely black, but would have been painted green at the Tarpen factory). The only bit I'm not completely certain about is the handle. I've got a feeling it should be green, like the rest of the machine, but I haven't found any green paint on it yet (although it's one of the last pieces to be stripped & is still waiting it's turn). I'm even wondering if this isn't the original handle???

So, here I am, surrounded by bits of Tarpen, covered in paint stripper, disappearing in a pile of paint strippings & wire wool! I've managed to dismantle most of the bits & bobs, the drive flanges were easier than I expected, the generator came apart quite easily, but there's a pulley, a V belt pulley, from the generator side of the flexible coupling. This powers a little aluminium fan inside the engine cowling. I simply can't get the damn thing off! I tried a puller, only to find out it's made of cast iron & I've broken a couple of bits off it!

I've even managed to get it to the end of the shaft, by using a blow lamp, a few different hammers & lots of swearing, but it refuses to go any further.

I'm now thinking I will drill 3 carefully spaced holes in it & try my harmonic puller (the one pictured on the flywheel). If I have to break the damn pulley than so be it! I've already found an aluminium replacement on eBay for under £20, so it won't be the end of the world.

Right! So, there's much of the story so far. Yesterday I spent the whole day stripping paint, cleaning & degreasing components, here's some pics of a very productive day's work.....

Engine (supposedly a J.A.P. although it bears no marks whatsoever) degreased & ready for some barrel black....

Tank, centre of genny & fan shroud being stripped.....

First few bits stripped.....

Engine blacked & part way through polishing crank cases.....

All the bits I stripped during the day, safely tucked up for the night.......

Chassis cleaned & degreased, paint stripper applied to be left over night (last job).......

Next on my list, I've got to get that damned pulley off (one way or another) in order to get to the other end of the genny casing (& remove the armature from the genny, for safe storage), finish all the stripping (other end of genny, chassis & handle), then it's all the nuts, bolts & fastenings (clean, strip, degrease & generally get moving again), clean & degrease all the bearings (ready for replacing) then it'll be the preparation for painting; all those stripped bits will have to be sanded down, then a quick go over with some P500 wet & dry before application of a good primer.

I think, after all that, I will paint the top coat on all the bits prior to reassembly, then touch-up wherever needs touching up after it's all back together (or is that a really stupid idea??? It's been a while since I've painted an engine, & never to this kind of standard).

All ideas & suggestions welcome. Today will be a nothing day, but I will keep you all posted of any progress as & when it happens.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Fun to get carried away isn't it?

I'd always vote to paint before assembly, for what it's worth.

Paul

I'd always vote to paint before assembly, for what it's worth.

Paul

pauldg- A credit to the forum

- Posts : 300

Join date : 2012-06-30

Age : 47

Location : South Wiltshire

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Looking great so far mate should look great when finished

_________________

A stationary engine is like peeing your pants, everyone can see it but only you get that nice warm feeling:

A stationary engine is like peeing your pants, everyone can see it but only you get that nice warm feeling:

Abes- Admin

- Posts : 1269

Join date : 2011-07-24

Age : 65

Location : Ringwood

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Well done you've made good progress so far much to the annoyance of everyone else

Please keep us posted of your progress and fingers crossed you get the pulley off without breaking it.

Stu.

Please keep us posted of your progress and fingers crossed you get the pulley off without breaking it.

Stu.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Just stopped for a quick tea break, it was too late last night, by the time I had finished, to post anything (now there's dedication for you  , actually it's more a case of my dad leaning on me to get it done & out of his workshop

, actually it's more a case of my dad leaning on me to get it done & out of his workshop  ).

).

I've made some more progress, cleaned the mag up & put it back on, the engine's looking great now. I've also finished most of the paint stripping (last night) & started scrubbing all the nuts, bolts, washers, bearings etc etc with some 2 stroke & an old toothbrush.

Today I've continued the nut & bolt cleaning & finished it (I think, or I hope), done some more polishing, & just before I stopped I made a massive effort to get that pulley off. Sadly the pulley didn't make it. A few bits flew off just as I was centre punching some marks for some holes I was going to drill, the idea was to get my puller on there, but it's just too brittle. It's a shame, as I'm suddenly going all purist on this one (never been bothered by that stuff before), but it's hardly likely to be noticed, as it's quite well tucked away.

So that leaves the other end of the genny free for paint stripping, which I shall get on with later this afternoon/evening. I can't seem to get the bearing off that end, but d'ya know what? I think I will just leave it there & clean it up in situ!

I've also got to carefully brush down the armature, I won't go too mad on this as it's very old, has a lot of very old fabric on it (cotton impregnated insulation) & this bit really is irreplaceable. The commutator (copper bit where the brushes make contact, can you tell I used to be an electrician??? ) will need a clean up with some very fine wet&dry paper, which I have.

) will need a clean up with some very fine wet&dry paper, which I have.

I'll add some more pics as I go, after I finish tonight.

(I'm actually going to run out of jobs to do at this rate. I can't afford to buy any paint or primer, or anything else, until Tuesday, then I've got to wait for some bits to arrive after that, & I don't really want to start the final painting preparation until I've at least got some primer handy, so that'll slow me down a bit!)

I've made some more progress, cleaned the mag up & put it back on, the engine's looking great now. I've also finished most of the paint stripping (last night) & started scrubbing all the nuts, bolts, washers, bearings etc etc with some 2 stroke & an old toothbrush.

Today I've continued the nut & bolt cleaning & finished it (I think, or I hope), done some more polishing, & just before I stopped I made a massive effort to get that pulley off. Sadly the pulley didn't make it. A few bits flew off just as I was centre punching some marks for some holes I was going to drill, the idea was to get my puller on there, but it's just too brittle. It's a shame, as I'm suddenly going all purist on this one (never been bothered by that stuff before), but it's hardly likely to be noticed, as it's quite well tucked away.

So that leaves the other end of the genny free for paint stripping, which I shall get on with later this afternoon/evening. I can't seem to get the bearing off that end, but d'ya know what? I think I will just leave it there & clean it up in situ!

I've also got to carefully brush down the armature, I won't go too mad on this as it's very old, has a lot of very old fabric on it (cotton impregnated insulation) & this bit really is irreplaceable. The commutator (copper bit where the brushes make contact, can you tell I used to be an electrician???

I'll add some more pics as I go, after I finish tonight.

(I'm actually going to run out of jobs to do at this rate. I can't afford to buy any paint or primer, or anything else, until Tuesday, then I've got to wait for some bits to arrive after that, & I don't really want to start the final painting preparation until I've at least got some primer handy, so that'll slow me down a bit!)

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

What a cracking in depth and comprehensive report, very well put together and almost feels as if your there with it, great stuff, keep us posted, was offered one for £20 about 3 years ago and snubbed it , wish i hadnt now.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Looks like things could fall into place quite nicely. I'm completely broke until Tuesday, so can't get any primer until then, but tonight I finished all my paint stripping, plus many other bits which I will come to in a minute, so that leaves a lazy day of sanding tomorrow, before I get my hands on some primer on Tuesday.

OK, so this afternoon/evening I did a load more polishing, so I've got most (probably all) of the shiny bits ready for assembly, quick pic.....

I did my last bit of paint stripping (thank god for that!)......

I've sorted all my nuts, bolts & bearings & freed up what I can......

I even took the plug socket & switch innards apart & gave them the full works.....

I cleaned up the armature & commutator, as promised, & did my best to clean all the old grease & gunk out of the remaining bearing (the one I was too scared to get off).....

Then, I gave the exhaust a few coats of that high temperature paint (after a good strip, wire brush & sand)......

I also cut some new metric bolts for the rope start pulley on the flywheel. I had some trouble with this earlier, whilst trying to get the flywheel off I broke a piece off this starter-pulley with a puller, so I ground it down a bit & made a tiny groove along both faces & I've stuck it back together with some QuickSteel putty. I'm going to give it a proper strength test, as I don't want it flying off whilst running. If it's no good I'll just leave it for now until I can afford to have it properly aluminium welded......

& finally, just before bed, I decided to have a go at the generator output wiring. It's very old stuff so I've wrapped some of it in insulation tape & applied some heat-shrink sleeving to the worst of it, I had to use a couple of modern cable ties, where string had previously been, then I re-made the ends of the wires off........

Then I dug out some old ceramic connector blocks. Silly really, as they won't be seen, but I like these little touches.....

& that's about it for today.

I would like to say a massive thank you for all the replies.

This restoration isn't really what I would call "Typical Me". I do have lots of other little projects, here & there, awaiting completion. My car's needed a new track-rod end since MOT in December (advisory). Normally I would take something like this apart & fiddle with it a bit, on & off, for months.

Normally I wouldn't be such a purist, insisting on factory colours, making sure all the right bits get painted, & all in the right colours. Admittedly even I think it would look better in British Racing Green with a couple of black stripes, like I had it before.

But, when I had that mag-flywheel off I knew the workshop was relatively free for a week or two, & I knew if I didn't do it now, I would probably NEVER do it, or would take it apart this winter & never get it back together.

So I took the opportunity, grabbed it with both hands, & I thought it would be nice to see what the old girl looked like when she first left the factory. It might not be to everyone's taste, it may not even be to mine, but I can't wait to see what it actually LOOKS like.

Look forward to some pics of primed Tarpen bits in the next few days, & a bit of a surprise with a couple of "different" cables I've sourced (should top it off really nicely).

OK, so this afternoon/evening I did a load more polishing, so I've got most (probably all) of the shiny bits ready for assembly, quick pic.....

I did my last bit of paint stripping (thank god for that!)......

I've sorted all my nuts, bolts & bearings & freed up what I can......

I even took the plug socket & switch innards apart & gave them the full works.....

I cleaned up the armature & commutator, as promised, & did my best to clean all the old grease & gunk out of the remaining bearing (the one I was too scared to get off).....

Then, I gave the exhaust a few coats of that high temperature paint (after a good strip, wire brush & sand)......

I also cut some new metric bolts for the rope start pulley on the flywheel. I had some trouble with this earlier, whilst trying to get the flywheel off I broke a piece off this starter-pulley with a puller, so I ground it down a bit & made a tiny groove along both faces & I've stuck it back together with some QuickSteel putty. I'm going to give it a proper strength test, as I don't want it flying off whilst running. If it's no good I'll just leave it for now until I can afford to have it properly aluminium welded......

& finally, just before bed, I decided to have a go at the generator output wiring. It's very old stuff so I've wrapped some of it in insulation tape & applied some heat-shrink sleeving to the worst of it, I had to use a couple of modern cable ties, where string had previously been, then I re-made the ends of the wires off........

Then I dug out some old ceramic connector blocks. Silly really, as they won't be seen, but I like these little touches.....

& that's about it for today.

I would like to say a massive thank you for all the replies.

This restoration isn't really what I would call "Typical Me". I do have lots of other little projects, here & there, awaiting completion. My car's needed a new track-rod end since MOT in December (advisory). Normally I would take something like this apart & fiddle with it a bit, on & off, for months.

Normally I wouldn't be such a purist, insisting on factory colours, making sure all the right bits get painted, & all in the right colours. Admittedly even I think it would look better in British Racing Green with a couple of black stripes, like I had it before.

But, when I had that mag-flywheel off I knew the workshop was relatively free for a week or two, & I knew if I didn't do it now, I would probably NEVER do it, or would take it apart this winter & never get it back together.

So I took the opportunity, grabbed it with both hands, & I thought it would be nice to see what the old girl looked like when she first left the factory. It might not be to everyone's taste, it may not even be to mine, but I can't wait to see what it actually LOOKS like.

Look forward to some pics of primed Tarpen bits in the next few days, & a bit of a surprise with a couple of "different" cables I've sourced (should top it off really nicely).

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Some bits I ordered last week arrived this morning, I've got some rather nice, rather pricey, HT lead, a very nice brass end cap for it (twice the price of the normal brass plug connectors, but it'll look good) & a few grommets, for various holes.......

Close up of HT lead.......

Anyway, I'd better get some sanding done. Might even get the soldering iron out & attach that HT lead.

Close up of HT lead.......

Anyway, I'd better get some sanding done. Might even get the soldering iron out & attach that HT lead.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Your doing a great job, you'll be very proud of it when finished I'm sure. You could always paint it original for now and if you don't like it change it after a few rallies,(I think you'll stick with the original paint.  )

)

This is a great in depth restoration and thanks for taking the time to share it with us.

Stu.

This is a great in depth restoration and thanks for taking the time to share it with us.

Stu.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

...continued from my petter genset post...

Not that I'm considering getting rid of it, but it'd go nicely with something like this:

Paul

Not that I'm considering getting rid of it, but it'd go nicely with something like this:

Paul

pauldg- A credit to the forum

- Posts : 300

Join date : 2012-06-30

Age : 47

Location : South Wiltshire

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

nice job so far ...

keep up the work

may i comment i like your can of esi start

would love a can just for display

would love a can just for display

matt

keep up the work

may i comment i like your can of esi start

matt

matt86- Admin

- Posts : 5577

Join date : 2011-03-29

Age : 38

Location : swindon/ faringdon

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

matt86 wrote:nice job so far ...

keep up the work

may i comment i like your can of esi start

would love a can just for display

matt

Beat me to it

love it

love it

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Trust me, that is only for display. If I ever catch him using it he's in trouble

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Not sure where the can of Easi-Start came from, will have to ask my dad. I'm not so sure it actually damages these old engines so much Ian, but I prefer to use lighter petrol anyway, if I'm having trouble.

Anyway, I spent the day sanding, as promised. Not much to report, except that I'm all done, ready & waiting to apply some primer, & I can't wait!

I also got bored this evening, with nothing to do, so I cleaned up the old mica 3-part spark plug. I'm not sure if it'll work again, but it looks nice.

First thing this morning (well, first thing for me, probably half way through the day for most of you) I soldered the new HT lead onto the mag coil, then soldered on my new brass end piece.

Here's a few pics of today's progress.......

Now I've got a problem though; the V belt pulley I thought would fit will not! It is a V belt pulley, but it's for an A section V belt. It's all very confusing, & I'm learning all about the different types of drive belts VERY quickly!

It is a V belt pulley, but it's for an A section V belt. It's all very confusing, & I'm learning all about the different types of drive belts VERY quickly!

I think mine is a Z section, especially as it has Z stamped on the belt, just before the number, & it measures 10mm across the top of the belt, which is what a Z section belt measures, evidently

So, I need a 5 inch pulley, for a Z section V belt, with a 3/4 inch bore. This can either have a key or a grub screw to locate it in the key groove (which is what the last one had).

My dad's mate (who does up old bikes) has a lathe, so I can ask to borrow it, if needs be. I've also been looking on line & have a few numbers to ring tomorrow, see what's available off the shelf. So far all I've found is the right pulley, but with some weird "Taper Lock System" thingy in the middle, which is another separate part which needs matching up & buying.

I knew something would just have to come along & slow me down, it was all going far too well!

Anyway, I spent the day sanding, as promised. Not much to report, except that I'm all done, ready & waiting to apply some primer, & I can't wait!

I also got bored this evening, with nothing to do, so I cleaned up the old mica 3-part spark plug. I'm not sure if it'll work again, but it looks nice.

First thing this morning (well, first thing for me, probably half way through the day for most of you) I soldered the new HT lead onto the mag coil, then soldered on my new brass end piece.

Here's a few pics of today's progress.......

Now I've got a problem though; the V belt pulley I thought would fit will not!

I think mine is a Z section, especially as it has Z stamped on the belt, just before the number, & it measures 10mm across the top of the belt, which is what a Z section belt measures, evidently

So, I need a 5 inch pulley, for a Z section V belt, with a 3/4 inch bore. This can either have a key or a grub screw to locate it in the key groove (which is what the last one had).

My dad's mate (who does up old bikes) has a lathe, so I can ask to borrow it, if needs be. I've also been looking on line & have a few numbers to ring tomorrow, see what's available off the shelf. So far all I've found is the right pulley, but with some weird "Taper Lock System" thingy in the middle, which is another separate part which needs matching up & buying.

I knew something would just have to come along & slow me down, it was all going far too well!

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Easy start will damage ANY engine, but I'm not going to dwell on that here and take this thread off topic.

Well done and lets hope you find a suitable pulley soon, maybe stick a wanted ad on this forum and the other forums, there are some very helpful people on the stationary engine forum network

Well done and lets hope you find a suitable pulley soon, maybe stick a wanted ad on this forum and the other forums, there are some very helpful people on the stationary engine forum network

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Not to worry, I've ordered a new one.

I researched it, found out about all the different types of V belts, found technical drawings of the pulley & the taper-lock bush, checked it all out &, I think, I will have the right one coming in the next few days.

From my measurements I reckon I had a choice of one slightly larger or one slightly smaller in overall diameter, so I've picked the one I thought would be best.

The taper-lock bush system is a very clever device, used in pulleys & sprockets. It means you choose your pulley/sprocket, which will have a large diameter tapered bore, you then order the correct sized taper-lock bush which will have the correct sized bore for your particular shaft. A clever system for matching up pulleys & sprockets with different sized shafts.

BTW, I also wanted to mention the Dremmel type machine I've been using. Mine's not a real Dremmel, it's an Argos version, but I've found it absolutely invaluable during this restoration, I often find myself using it for all sorts of different jobs.

They're not expensive tools by any means. I also have a big selection of different bits for it, which came from Lidl, allsorts of grinding stones, sanding discs/drums, polishing mops, cutting discs etc etc. Really good for detail work, & excellent for getting into those hard to reach spaces, like into corners to remove years worth of oil & encrusted crud, ready for painting.

I keep mine permanently hooked-up in the workshop. It came with a stand thingy, which you hang it from, & leave the flexi-drive shaft attached, then you just put whatever bit you need on, & use it, holding it a bit like a pencil. So easy &, for a small tool, very effective.

Anyway, I'm off to look for some primer, & see if I can find this paint a bit cheaper somewhere else.

I researched it, found out about all the different types of V belts, found technical drawings of the pulley & the taper-lock bush, checked it all out &, I think, I will have the right one coming in the next few days.

From my measurements I reckon I had a choice of one slightly larger or one slightly smaller in overall diameter, so I've picked the one I thought would be best.

The taper-lock bush system is a very clever device, used in pulleys & sprockets. It means you choose your pulley/sprocket, which will have a large diameter tapered bore, you then order the correct sized taper-lock bush which will have the correct sized bore for your particular shaft. A clever system for matching up pulleys & sprockets with different sized shafts.

BTW, I also wanted to mention the Dremmel type machine I've been using. Mine's not a real Dremmel, it's an Argos version, but I've found it absolutely invaluable during this restoration, I often find myself using it for all sorts of different jobs.

They're not expensive tools by any means. I also have a big selection of different bits for it, which came from Lidl, allsorts of grinding stones, sanding discs/drums, polishing mops, cutting discs etc etc. Really good for detail work, & excellent for getting into those hard to reach spaces, like into corners to remove years worth of oil & encrusted crud, ready for painting.

I keep mine permanently hooked-up in the workshop. It came with a stand thingy, which you hang it from, & leave the flexi-drive shaft attached, then you just put whatever bit you need on, & use it, holding it a bit like a pencil. So easy &, for a small tool, very effective.

Anyway, I'm off to look for some primer, & see if I can find this paint a bit cheaper somewhere else.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

I do like the cloth covered HT lead your using, I'm thinking about changing some of my old engines to it as I think it looks a lot better.

If you need help to source a new pulley there's plenty of suppliers about but they are expensive and I don't think look right a shiney new alloy pulley on an old engine.

I have to add my bit on the easy start can and think this is the best, maybe not for starting but just the name helps a lot

https://www.youtube.com/watch?v=pxM9-TQ88Wk

Stu.

If you need help to source a new pulley there's plenty of suppliers about but they are expensive and I don't think look right a shiney new alloy pulley on an old engine.

I have to add my bit on the easy start can and think this is the best, maybe not for starting but just the name helps a lot

https://www.youtube.com/watch?v=pxM9-TQ88Wk

Stu.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Have you not got any local paint suppliers, I have one localish and buy machine enamal at a good price with plenty of choice for colours, he can aslo mix up any colour you want if yyou can supply the code for the colour.

It's interesting what your saying about the taper lock bush and pullies as I won some on ebay a few months back for 99p, the seller wasn't very happy as he had a buy it now of £60 so you can tellby that how many there was and all of the brand new. I'd never had anything to do with this system and I thought I'd just be able to use a few on my small engines if I made the center hole bigger but once I checked out how they work it's a great idea.

Stu.

It's interesting what your saying about the taper lock bush and pullies as I won some on ebay a few months back for 99p, the seller wasn't very happy as he had a buy it now of £60 so you can tellby that how many there was and all of the brand new. I'd never had anything to do with this system and I thought I'd just be able to use a few on my small engines if I made the center hole bigger but once I checked out how they work it's a great idea.

Stu.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Right then, I've found a local paint supplier who can get me the paint I want, & it works out about a fiver cheaper than the other lot on line. Still expensive though.

I also bought some Hammerite Special Metals Primer, mainly for the aluminium, but it'll do for everything.

I've ordered the pulley, ordered the "TARPEN" vinyl lettering for the petrol tank (not sure how that's going to turn out) & I've ordered some special flex for the run from generator output to plug socket & governor.

I completely forgot to buy some gloss black paint, I've got to wait until Thursday for the green paint to arrive (the shop has had to order it in special) but I will go back there tomorrow & get some black (a very small tin) so I can get on with the handle, plug socket & wheels.

I also bought a couple of condensers, one for this & one for my brother's Stuart Turner (which still won't start! ).

).

So, here's a pic of all my lovely primed bits of Tarpen......

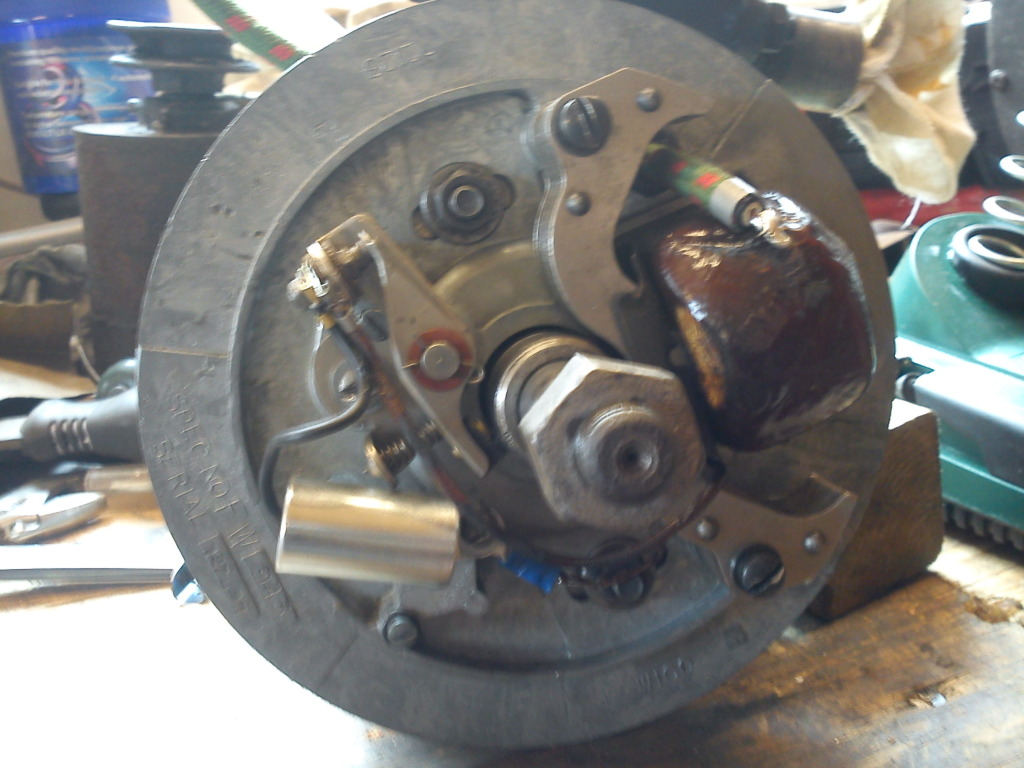

& the magneto, with new condenser, points all gapped & ready to go.......

Tomorrow I'll pick up the gloss black & paint those bits, that'll get them out of the way. I may get some green paint on on Thursday, but it's not arriving until after lunch, so not sure how much I'll get done.

It's my mum's 60th birthday this weekend, & I've got to help out with the catering for her party on Saturday, so Friday will probably be taken up with that, although there's always the evening.

Once the new pulley arrives (they tell me it has been shipped this afternoon) I will prime & paint it green, hopefully it'll blend in nicely, it's hardly in plain sight, so shouldn't stick out like a sore thumb.

I'm hoping reassembly will happen sometime early next week, might even possibly get started with it on Sunday afternoon, if we can get rid of all the visiting relatives for my mum's 60th (if only these people knew just how much they're inconveniencing me ). Not bad really, I realised today that I only took it all apart last Wednesday (4th of July, my birthday funnily enough), so this marks the end of day 7, I reckon that's gotta be close to some kind of record!

). Not bad really, I realised today that I only took it all apart last Wednesday (4th of July, my birthday funnily enough), so this marks the end of day 7, I reckon that's gotta be close to some kind of record!

I promise to take my time with the next one

I also bought some Hammerite Special Metals Primer, mainly for the aluminium, but it'll do for everything.

I've ordered the pulley, ordered the "TARPEN" vinyl lettering for the petrol tank (not sure how that's going to turn out) & I've ordered some special flex for the run from generator output to plug socket & governor.

I completely forgot to buy some gloss black paint, I've got to wait until Thursday for the green paint to arrive (the shop has had to order it in special) but I will go back there tomorrow & get some black (a very small tin) so I can get on with the handle, plug socket & wheels.

I also bought a couple of condensers, one for this & one for my brother's Stuart Turner (which still won't start!

So, here's a pic of all my lovely primed bits of Tarpen......

& the magneto, with new condenser, points all gapped & ready to go.......

Tomorrow I'll pick up the gloss black & paint those bits, that'll get them out of the way. I may get some green paint on on Thursday, but it's not arriving until after lunch, so not sure how much I'll get done.

It's my mum's 60th birthday this weekend, & I've got to help out with the catering for her party on Saturday, so Friday will probably be taken up with that, although there's always the evening.

Once the new pulley arrives (they tell me it has been shipped this afternoon) I will prime & paint it green, hopefully it'll blend in nicely, it's hardly in plain sight, so shouldn't stick out like a sore thumb.

I'm hoping reassembly will happen sometime early next week, might even possibly get started with it on Sunday afternoon, if we can get rid of all the visiting relatives for my mum's 60th (if only these people knew just how much they're inconveniencing me

I promise to take my time with the next one

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

What a great step by step restoration!

Well done!

The set is looking really good so far

Adam

Well done!

The set is looking really good so far

Adam

_________________

Wolseley WD2+H2 Pump

Bamford EG1

Petter M and 110v Dynamo

Lister D

Petter AA1

Plus Many more Aircooled Engines

Statman- Life Member

- Posts : 697

Join date : 2009-07-21

Age : 38

Location : PENZANCE,CORNWALL

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

Your doing a great job and thanks for keeping us informed of how your getting on it's all very interesting. You'll need to let the gloss paint harden before doing to much with the engine or you'll make a mess of the paint and thus waisting time and money. (speaking from experience LOL)

Stu.

Stu.

Guest- Guest

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

stationary stu wrote:You'll need to let the gloss paint harden before doing to much with the engine or you'll make a mess of the paint and thus waisting time and money. (speaking from experience LOL)

Stu.

That could fall into place nicely then. If I can get the painting done before the weekend I can leave it all in the workshop to harden off a bit, while we deal with my mum's 60th birthday & all the visiting relatives (I really can't wait to get it back together, so I'll need to slow down a bit, as you're quite right, I don't wanna make a mess of it).

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Nutgone's Tarpen

Re: Nutgone's Tarpen

I've been & bought some black gloss this morning, & found some "Auto Glym" Bumper Care Gel in the garage, I will use this on the tyres, see how it brings them up.

Will report back later, with a few pics.

Will report back later, with a few pics.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Page 1 of 4 • 1, 2, 3, 4

Similar topics

Similar topics» Second Purchase

» Here We Go Again! Tarpen Take 2

» I'm at it again! Tarpen Resto No. 3

» Tarpen generating set

» Villiers Tarpen restore

» Here We Go Again! Tarpen Take 2

» I'm at it again! Tarpen Resto No. 3

» Tarpen generating set

» Villiers Tarpen restore

Page 1 of 4

Permissions in this forum:

You cannot reply to topics in this forum