Cutting Gaskets

+8

Garak

chiefy

Steve H

tony RA

matt86

DanBoy

Ianhw77k

nutgone

12 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Cutting Gaskets

Cutting Gaskets

Firstly I must say:

I am by no means a specialist in this field, all I've done is use what common sense I have, coupled with any engineering knowledge rattling around up there with the loose screws & marbles, & just "had a go", basically a bit of trial & error.

What I'm about to discuss is entirely what I've managed to pick up & teach myself. I am completely self taught when it comes to this & I would very much like others to add what they know.

I haven't by any means made a comprehensive list of how to cut all gaskets in all different types of gasket medium, so I would love others to add what they can do & perhaps pass on some more knowledge. Maybe we could even make this a sticky topic in the future, a place for people to come when they need to cut a gasket?

I'll begin with what I've done today in the next post. I look forward to any feedback, & if anyone can tell me how to make this easier then by all means speak up.

I am by no means a specialist in this field, all I've done is use what common sense I have, coupled with any engineering knowledge rattling around up there with the loose screws & marbles, & just "had a go", basically a bit of trial & error.

What I'm about to discuss is entirely what I've managed to pick up & teach myself. I am completely self taught when it comes to this & I would very much like others to add what they know.

I haven't by any means made a comprehensive list of how to cut all gaskets in all different types of gasket medium, so I would love others to add what they can do & perhaps pass on some more knowledge. Maybe we could even make this a sticky topic in the future, a place for people to come when they need to cut a gasket?

I'll begin with what I've done today in the next post. I look forward to any feedback, & if anyone can tell me how to make this easier then by all means speak up.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Thin paper gasket

Thin paper gasket

Whilst doing this I thought I would take some pics. I actually ended up taking 39 pics! I won't bore you with them all here, there's an album for anyone who wants to be truly bored right here....

http://photobucket.com/nutgonesgaskets

OK, so here's the task, it's a bit of a complicated one, I need a gasket for the timing case on my little JAP Model 3. Here's the extent of the problem....

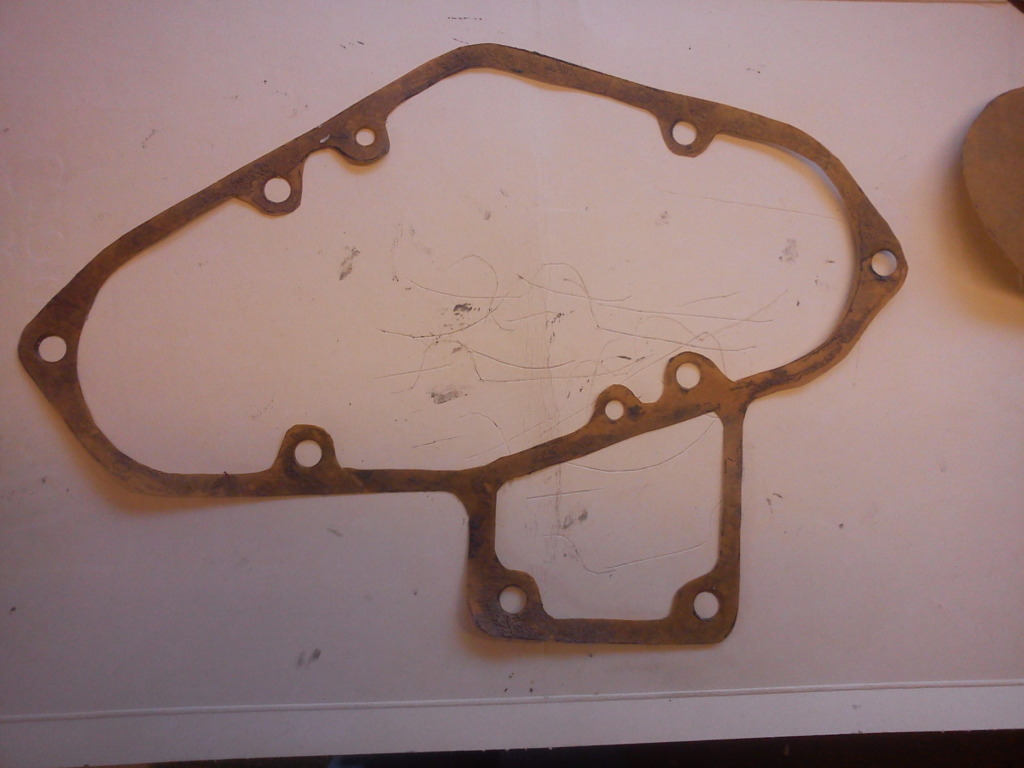

As you can see there is a dirty great cam shaft sticking out of the flat side of the joint, I can't use the engine side for marking as it's got all the studs & dowels sticking out of it. I do have a spare timing case though, but it's covered in dirt & the dreaded red stuff, which shall remain nameless, that people used to use instead of gaskets! After a quick scrape off & clean up with some fine wet & dry paper I've got myself a pattern....

Now I need some gasket material. As the title of this particular post suggests I want a thin paper gasket here. A few days ago I ordered some gasket paper from a company on eBay called TYM Seals, based in Devizes. They offered an assortment pack of different thicknesses of paper-type gasket material in A4 sheets. You get 5 sheets, one of each thickness, plus a couple of "free samples" of some other gasket materials. What I'm using here is quite similar to brown paper used for parcels, but I was feeling frivolous & decided to spend out on the proper stuff.....

I'm going with the thinnest one of the lot, literally paper thin. I've never cut gaskets from it before, so there could be some mistakes.

So, I've got my paper, & I've got my pattern, now I need some tools; Firstly I will need a sharp knife. I really wanted a scalpel, I went all over the place looking for them but failed to find any, so I've gone with the craft knifes instead. These ones have the blades you can snap off, so after each gasket I snap the blade off, ready for the next one. These knives aren't expensive either & are quite plentiful (your average pound shop should sell them, or something similar). I can't state it enough though, whatever you use needs to be super-sharp!....

Next I want some scissors. I just used one of a set of 3 I got from Ikea for a pound. They're actually pretty good scissors, doubt they'll last a lifetime, but they'll do for now. I also wanted something reasonably flat to work on, which could get scratched & cut & wouldn't matter, so I've used an old cereal box, opened out, on the workbench.

I also want something to make the holes for the studs & dowels to poke through. Now anything bigger than about 8 or 10mm I can cut by hand with the knife, but for smaller holes I really wanted some hollow punches. I scanned eBay for some & eventually settled on a set of 5 metric ones & a set of 6 imperial ones, these have left me with a hollow punch for just about any size hole from 8mm down (& they're not expensive. Try looking in "leather craft" sections)....

Now I've got my tools & paper I want something to make an impression of the pattern/template onto the gasket paper for me to cut round. I think it was Stu who suggested "Engineers Blue", which would easily be the best stuff to use, but I don't have any engineers blue, I do have a tin of black grease though, I tend to use it for everything, I got it for £2 from an army surplus stall at a rally, it should work well....

Now we need to coat the face of the joint well, but not too well. We want to make an accurate impression after all. Engineers blue is great stuff, a little goes a VERY long way, this black grease can be treated almost the same. We want to coat the face & then remove any excess which has gone over the sides, like this....

& into the holes, like this....

These extra bits would impair the accuracy we need for a good gasket. I just run my finger around the very edge, trying not to take the grease off the face, & I run a small piece of rag or kitchen roll, rolled into a point between your fingers, into each bolt hole. I can't emphasise enough though, we really only want a very thin layer on the face. If you don't have black grease or engineers blue then any oil based stuff will do, even just some oil from a squirt can should make an impression you can see to cut round. You may have to use your imagination, that's how I thought of the grease.

Then I carefully place the piece onto the gasket paper (which should be on it's smooth, flat, clean surface) & apply some good pressure, hopefully without smudging it....

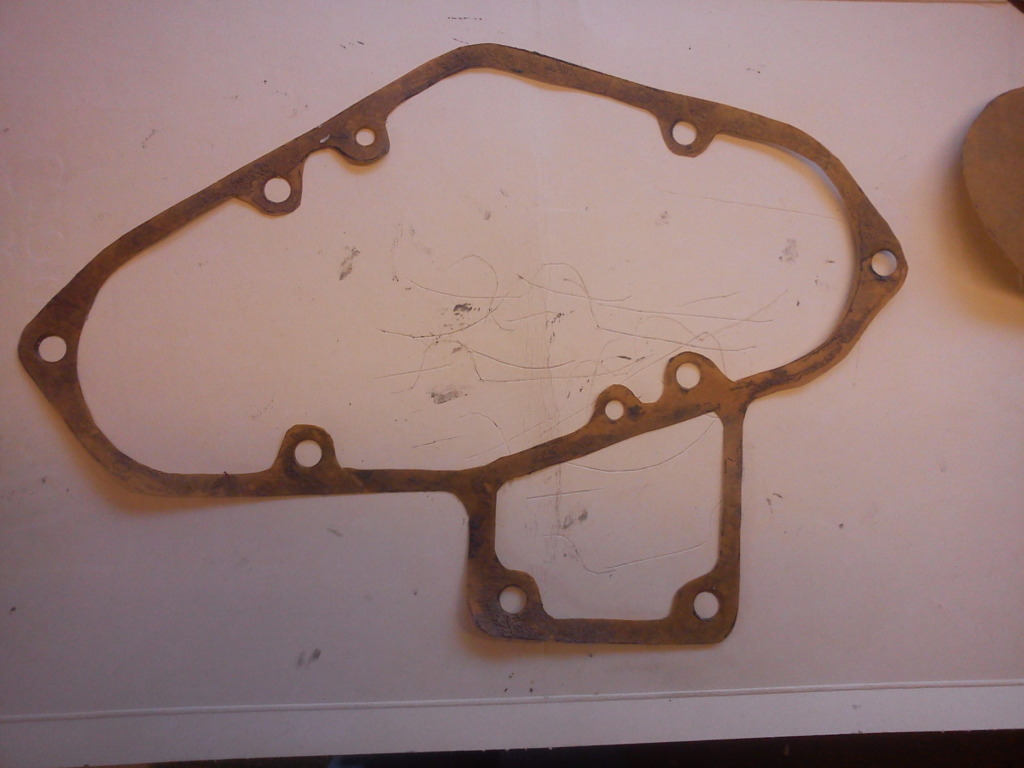

Then carefully peel it off the paper, or peel the paper off of it, without smudging, & it should look something like this....

This one's good, but by no means perfect, there's some bits missing here....

But there should be enough to go on I reckon.

Now, here's what I've found by trial & error, with a little common sense. I always cut out the middle of a gasket first, as you have the outside of the gasket paper to hold things steady for you, you can then use the scissors or the knife to cut round the outside. But I also think it's best to punch the holes BEFORE you do any of this.

So it's holes first (then I had a little try to see if it fits the studs)....

Not perfect, but it's pretty good for my first attempt at this one. Then I start with the smaller inside bits....

Then carry on with the inside bits....

Then I turn to the scissors for the outer line. I've found sometimes you're better off using the knife for this part, but if you're using old cornflake packets, or some other kind of disposable media, you can use the scissors to cut a rough outline, then pick it up & continue to use the scissors, or knife, or a combination of both, to complete the gasket. Sadly I'm not prepared to be so wasteful with my gasket paper, so I wanted to do the whole thing in one continuous cut. I used scissors for everything but the last two internal corners, where I went back to the knife....

& I ended up with a reasonable gasket. It's a bit thin in places & a bit thick in others, but it's not bad. I seem to be getting better the more I do with this....

I put it on & trimmed around the few places where it was poking out. You need to be careful with this though, if you're not a perfectionist then just leave it alone, but whatever you do try to resist the urge to tear or rip at it, as you could easily end up tearing the whole gasket!....

To sum up I would like to add; if in doubt- Go wide! You can always trim a little off, but you can't put it back.

I actually prefer this paper to the more fibrous materials available. But I did also cut a gasket from the more fibrous stuff. I'll say a bit about that in my next post.

Anyone got anything to add or can tell me any little tricks to make this a little easier???

http://photobucket.com/nutgonesgaskets

OK, so here's the task, it's a bit of a complicated one, I need a gasket for the timing case on my little JAP Model 3. Here's the extent of the problem....

As you can see there is a dirty great cam shaft sticking out of the flat side of the joint, I can't use the engine side for marking as it's got all the studs & dowels sticking out of it. I do have a spare timing case though, but it's covered in dirt & the dreaded red stuff, which shall remain nameless, that people used to use instead of gaskets! After a quick scrape off & clean up with some fine wet & dry paper I've got myself a pattern....

Now I need some gasket material. As the title of this particular post suggests I want a thin paper gasket here. A few days ago I ordered some gasket paper from a company on eBay called TYM Seals, based in Devizes. They offered an assortment pack of different thicknesses of paper-type gasket material in A4 sheets. You get 5 sheets, one of each thickness, plus a couple of "free samples" of some other gasket materials. What I'm using here is quite similar to brown paper used for parcels, but I was feeling frivolous & decided to spend out on the proper stuff.....

I'm going with the thinnest one of the lot, literally paper thin. I've never cut gaskets from it before, so there could be some mistakes.

So, I've got my paper, & I've got my pattern, now I need some tools; Firstly I will need a sharp knife. I really wanted a scalpel, I went all over the place looking for them but failed to find any, so I've gone with the craft knifes instead. These ones have the blades you can snap off, so after each gasket I snap the blade off, ready for the next one. These knives aren't expensive either & are quite plentiful (your average pound shop should sell them, or something similar). I can't state it enough though, whatever you use needs to be super-sharp!....

Next I want some scissors. I just used one of a set of 3 I got from Ikea for a pound. They're actually pretty good scissors, doubt they'll last a lifetime, but they'll do for now. I also wanted something reasonably flat to work on, which could get scratched & cut & wouldn't matter, so I've used an old cereal box, opened out, on the workbench.

I also want something to make the holes for the studs & dowels to poke through. Now anything bigger than about 8 or 10mm I can cut by hand with the knife, but for smaller holes I really wanted some hollow punches. I scanned eBay for some & eventually settled on a set of 5 metric ones & a set of 6 imperial ones, these have left me with a hollow punch for just about any size hole from 8mm down (& they're not expensive. Try looking in "leather craft" sections)....

Now I've got my tools & paper I want something to make an impression of the pattern/template onto the gasket paper for me to cut round. I think it was Stu who suggested "Engineers Blue", which would easily be the best stuff to use, but I don't have any engineers blue, I do have a tin of black grease though, I tend to use it for everything, I got it for £2 from an army surplus stall at a rally, it should work well....

Now we need to coat the face of the joint well, but not too well. We want to make an accurate impression after all. Engineers blue is great stuff, a little goes a VERY long way, this black grease can be treated almost the same. We want to coat the face & then remove any excess which has gone over the sides, like this....

& into the holes, like this....

These extra bits would impair the accuracy we need for a good gasket. I just run my finger around the very edge, trying not to take the grease off the face, & I run a small piece of rag or kitchen roll, rolled into a point between your fingers, into each bolt hole. I can't emphasise enough though, we really only want a very thin layer on the face. If you don't have black grease or engineers blue then any oil based stuff will do, even just some oil from a squirt can should make an impression you can see to cut round. You may have to use your imagination, that's how I thought of the grease.

Then I carefully place the piece onto the gasket paper (which should be on it's smooth, flat, clean surface) & apply some good pressure, hopefully without smudging it....

Then carefully peel it off the paper, or peel the paper off of it, without smudging, & it should look something like this....

This one's good, but by no means perfect, there's some bits missing here....

But there should be enough to go on I reckon.

Now, here's what I've found by trial & error, with a little common sense. I always cut out the middle of a gasket first, as you have the outside of the gasket paper to hold things steady for you, you can then use the scissors or the knife to cut round the outside. But I also think it's best to punch the holes BEFORE you do any of this.

So it's holes first (then I had a little try to see if it fits the studs)....

Not perfect, but it's pretty good for my first attempt at this one. Then I start with the smaller inside bits....

Then carry on with the inside bits....

Then I turn to the scissors for the outer line. I've found sometimes you're better off using the knife for this part, but if you're using old cornflake packets, or some other kind of disposable media, you can use the scissors to cut a rough outline, then pick it up & continue to use the scissors, or knife, or a combination of both, to complete the gasket. Sadly I'm not prepared to be so wasteful with my gasket paper, so I wanted to do the whole thing in one continuous cut. I used scissors for everything but the last two internal corners, where I went back to the knife....

& I ended up with a reasonable gasket. It's a bit thin in places & a bit thick in others, but it's not bad. I seem to be getting better the more I do with this....

I put it on & trimmed around the few places where it was poking out. You need to be careful with this though, if you're not a perfectionist then just leave it alone, but whatever you do try to resist the urge to tear or rip at it, as you could easily end up tearing the whole gasket!....

To sum up I would like to add; if in doubt- Go wide! You can always trim a little off, but you can't put it back.

I actually prefer this paper to the more fibrous materials available. But I did also cut a gasket from the more fibrous stuff. I'll say a bit about that in my next post.

Anyone got anything to add or can tell me any little tricks to make this a little easier???

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

Basically all you need is a small ball pein hammer and some gasket paper. There is tools to cut holes out but a small pair of scissors can do the job. Or another way is get some engineers blue put a very thin smear on the face, press down the gasket paper and it makes an impression on the paper then cut it out.

I don't know of any other methods so looking forward to seeing if anyone makes them different.

Here's your shopping list!!!

http://www.ebay.co.uk/itm/GASKET-PAPER-SHEET-0-8MMTHK-A4-size-genuine-flexoid-2-sheets-per-set-/330790873066?pt=UK_CarsParts_Vehicles_BoatEquipment_Accessories_SM&hash=item4d04ac27ea

http://www.ebay.co.uk/itm/BALL-PEIN-HAMMER-HARDWOOD-8oz-/320775445517?pt=UK_Hand_Tools_Equipment&hash=item4aafb4dc0d

http://www.ebay.co.uk/itm/38G-TIN-STUARTS-MICROMETER-ENGINEERS-MARKING-BLUE-/350492469965?pt=UK_BOI_Metalworking_Milling_Welding_Metalworking_Supplies_ET&hash=item519afaaacd

http://www.ebay.co.uk/itm/9pc-HOLLOW-PUNCH-SET-LEATHER-PUNCH-SET-CARD-PAPER-PLASTIC-GASKET-2-5-10mm-punch-/270875320830?pt=UK_Crafts_Leathercraft_LE&hash=item3f116d61fe

http://www.ebay.co.uk/itm/SET-OF-3-STAINLESS-STEEL-QUALITY-SCISSORS-CRAFT-KITCHEN-SEWING-SCISSOR-SCISSORS-/190585578733?pt=UK_Kitchen_Accessories&hash=item2c5fc924ed

Just for Nuts

http://www.ebay.co.uk/itm/VHT-COPPER-CORK-PAPER-METAL-WATER-PUMP-SUMP-HEAD-GASKET-SEALER-CEMENT-SP21-/350572555642?pt=UK_CarsParts_Vehicles_CarParts_SM&hash=item519fc0ad7a

Stu.

I don't know of any other methods so looking forward to seeing if anyone makes them different.

Here's your shopping list!!!

http://www.ebay.co.uk/itm/GASKET-PAPER-SHEET-0-8MMTHK-A4-size-genuine-flexoid-2-sheets-per-set-/330790873066?pt=UK_CarsParts_Vehicles_BoatEquipment_Accessories_SM&hash=item4d04ac27ea

http://www.ebay.co.uk/itm/BALL-PEIN-HAMMER-HARDWOOD-8oz-/320775445517?pt=UK_Hand_Tools_Equipment&hash=item4aafb4dc0d

http://www.ebay.co.uk/itm/38G-TIN-STUARTS-MICROMETER-ENGINEERS-MARKING-BLUE-/350492469965?pt=UK_BOI_Metalworking_Milling_Welding_Metalworking_Supplies_ET&hash=item519afaaacd

http://www.ebay.co.uk/itm/9pc-HOLLOW-PUNCH-SET-LEATHER-PUNCH-SET-CARD-PAPER-PLASTIC-GASKET-2-5-10mm-punch-/270875320830?pt=UK_Crafts_Leathercraft_LE&hash=item3f116d61fe

http://www.ebay.co.uk/itm/SET-OF-3-STAINLESS-STEEL-QUALITY-SCISSORS-CRAFT-KITCHEN-SEWING-SCISSOR-SCISSORS-/190585578733?pt=UK_Kitchen_Accessories&hash=item2c5fc924ed

Just for Nuts

http://www.ebay.co.uk/itm/VHT-COPPER-CORK-PAPER-METAL-WATER-PUMP-SUMP-HEAD-GASKET-SEALER-CEMENT-SP21-/350572555642?pt=UK_CarsParts_Vehicles_CarParts_SM&hash=item519fc0ad7a

Stu.

Guest- Guest

Re: Cutting Gaskets

Re: Cutting Gaskets

Just to add a bit make sure you cut out ALL holes as some may not be for studs or bolts they could be an oil way.

You've done a cracking job Nuts, don't think there's anything more that would improve it. Just take your time and it's worth keeping all the biggish off cuts as they could be used on small projects.

Stu.

You've done a cracking job Nuts, don't think there's anything more that would improve it. Just take your time and it's worth keeping all the biggish off cuts as they could be used on small projects.

Stu.

Guest- Guest

Fibre based gasket material

Fibre based gasket material

Next I wanted to cut one from some different material, I wanted to use this grey coloured stuff, on top of the pile here....

& here's the part I want to cut the gasket for....

It may look easy enough, but it's got a tricky little lip on it, take a closer look....

So it's that lip I shall start with. Using the grease, as before, I make an outline....

After cutting round it I need to make an impression of the rest of the joint face. So I decided to hold the bulbous part in the vice, smear it with grease & carefully place the gasket, with the hole cut in it, around it & apply pressure around the face.

This all went well until the part slipped out of the vice (hope the neighbours weren't listening

(hope the neighbours weren't listening  ). But I was almost done, i managed to carefully place the paper back on & finish off my impression. I immediately stamped out the holes....

). But I was almost done, i managed to carefully place the paper back on & finish off my impression. I immediately stamped out the holes....

It was then just a case of cutting it out & checking it fits. Quite simple really.

I just wanted to add a little about the differences between this stuff & the paper based gasket materials.

This stuff doesn't cut as well. After cutting out my circle on this gasket I went to remove the inner piece, but despite my best efforts the knife hadn't cut completely through all the way around. The natural thing you want to do here is just give it a little pull, it's been scored, why shouldn't it just come off???

Trouble is it tends to tear unevenly, leaving an edge like this....

Not so bad here, but on a smaller, more fiddly gasket you could end up ruining the whole thing. So it'a always best to avoid that temptation to pull, rip or tear at these gasket materials. That's what I've found at least.

& here's the part I want to cut the gasket for....

It may look easy enough, but it's got a tricky little lip on it, take a closer look....

So it's that lip I shall start with. Using the grease, as before, I make an outline....

After cutting round it I need to make an impression of the rest of the joint face. So I decided to hold the bulbous part in the vice, smear it with grease & carefully place the gasket, with the hole cut in it, around it & apply pressure around the face.

This all went well until the part slipped out of the vice

It was then just a case of cutting it out & checking it fits. Quite simple really.

I just wanted to add a little about the differences between this stuff & the paper based gasket materials.

This stuff doesn't cut as well. After cutting out my circle on this gasket I went to remove the inner piece, but despite my best efforts the knife hadn't cut completely through all the way around. The natural thing you want to do here is just give it a little pull, it's been scored, why shouldn't it just come off???

Trouble is it tends to tear unevenly, leaving an edge like this....

Not so bad here, but on a smaller, more fiddly gasket you could end up ruining the whole thing. So it'a always best to avoid that temptation to pull, rip or tear at these gasket materials. That's what I've found at least.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

stationary stu wrote:Just to add a bit make sure you cut out ALL holes as some may not be for studs or bolts they could be an oil way.

You've done a cracking job Nuts, don't think there's anything more that would improve it. Just take your time and it's worth keeping all the biggish off cuts as they could be used on small projects.

Stu.

Quite right on all counts Stu. Take your time is an important one, make sure you're comfortable with the direction you're cutting in (I call it the "Gasket Cutters Dance" around the workbench as you change your position around the knife

& I completely forgot about saving the off-cuts, you'd be surprised how useful the smallest bits can be....

Cheers Stu

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

I would like to know a little more about cutting gaskets in these composite materials with metal inside them???

I have tried using a drill to cut holes in gasket paper before but it always rips the paper. I would guess it needs to be clamped between 2 pieces of wood or something, but if you do that how do you know exactly where to drill???

My guess is you need to mark out your template on a piece of wood, clamp the gasket material between that & another piece of wood, then drill the holes in it, then remove it & finish cutting the gasket.

I know some of these modern "non-asbestos" gasket materials actually cut very easily, but they don't contain any metal either. I have some in the shed (well, Ianhw77k has some in the shed), next time we use it for anything I'll take some pics & do a little write-up.

I have tried using a drill to cut holes in gasket paper before but it always rips the paper. I would guess it needs to be clamped between 2 pieces of wood or something, but if you do that how do you know exactly where to drill???

My guess is you need to mark out your template on a piece of wood, clamp the gasket material between that & another piece of wood, then drill the holes in it, then remove it & finish cutting the gasket.

I know some of these modern "non-asbestos" gasket materials actually cut very easily, but they don't contain any metal either. I have some in the shed (well, Ianhw77k has some in the shed), next time we use it for anything I'll take some pics & do a little write-up.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

I've never had anything to do with the gasket paper with metal in them, can you not just use your hole punch to make the holes?

Stu.

Stu.

Guest- Guest

Re: Cutting Gaskets

Re: Cutting Gaskets

stationary stu wrote:I've never had anything to do with the gasket paper with metal in them, can you not just use your hole punch to make the holes?

Stu.

I suppose you could do, it's only very thin metal after all.

Mind you, the non-asbestos type materials, like Tesnit, are pretty tough (tough enough for use as head gaskets for open crank engines & Stuart Turners) & they don't contain any metal at all.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

What I'd like to know is any tricks to cutting a gasket from a sheet of copper as I'd like to do this myself soon.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

Ianhw77k wrote:What I'd like to know is any tricks to cutting a gasket from a sheet of copper as I'd like to do this myself soon.

When I were a lad (tee-hee) I worked for a local newspaper in the photo department. The old method of making plates was to use copper sheet and a light sensitive dye. To cut things short, basically the negative would be laid over the sheet and light applied which would "set" the dye. The whole plate was then acid etched. I suppose a similar process could be adapted for making copper gaskets, although I suspect it would be easier to to use Computer Aided Design tools nowadays. Ask at your local engineering firm. They may be able to help, or at least, they may have a catalogue of ready made gaskets/shims which could be adapted. (Usually round ones only).

If you really want give it a go yourself then Nutgone's piece still stands as long as you are using thin copper. The hole punches should work but you might need a roller blade (glass cutting tool) to cut the copper. All edges would need dressing as well.

_________________

I intend to live forever - so far, so good!

DanBoy- Life Member

- Posts : 622

Join date : 2012-01-09

Location : Burntwood, Staffordshire

Re: Cutting Gaskets

Re: Cutting Gaskets

Thanks for that Dan, sounds like too much trouble for me though

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Cutting Gaskets

Re: Cutting Gaskets

the type of gasket you mention with steel in the middle are a real paint to get tin snips just fold them in half .... so i resorted to a angle grinder and hole punches ..... bearing in mind my hole punches are now blunt

matt

matt

matt86- Admin

- Posts : 5577

Join date : 2011-03-29

Age : 38

Location : swindon/ faringdon

Re: Cutting Gaskets

Re: Cutting Gaskets

Hi Matt in you/r 1s/t &2n/d pics I would roughly cut out inside of the gasket first wipe the gasket surface with bit of super glue on you/r finger pop the gasket paper on give a bit of a rub or press and cutting the holes (with no threads )I use a ball bearing a tad bigger than hole you/r working on placed over the hole you/l feel this under light pressure and sharp tap with a small hammer and all holes in the right places sometimes you can use a mole grips instead of a hammer if/s a thin casing then trim inner & outer with you/r craft knife

Hope this helps

Hope this helps

tony RA- A credit to the forum

- Posts : 279

Join date : 2013-11-16

Age : 77

Location : newtown powys

Re: Cutting Gaskets

Re: Cutting Gaskets

Instead of using the grease/engineers blue marking method,I stick the item on the photo copy at work,and then use the print as a template.

I always keep a copy of the print in a folder,ready for the next time.

Steve

I always keep a copy of the print in a folder,ready for the next time.

Steve

_________________

Go on I'll have a go at getting it going

Steve H- I really need to post more

- Posts : 8

Join date : 2015-01-28

Re: Cutting Gaskets

Re: Cutting Gaskets

Hi Matt,

I got my scalpel and blades from ebay - just search for Swann Morton.

I got my scalpel and blades from ebay - just search for Swann Morton.

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2818

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Cutting Gaskets

Re: Cutting Gaskets

I remember as a lad my dad making gaskets from brown paper i think it may have been Kraft paper but not sure as stuff like that was hard to come by inthe late 1940s,i recall him coating the area that needed a gasket witha marking medium it could have been engineers blue as that was his proffession,he would lightly tap round the outside with a light ball pein hammer,this then shows the outline to be cut out and also the various holes,he made his own punches out of rod this on a Drummond flatbed lathe of 1905 vintage this was foot treadled that was sometimes my job,I still have the lathe although it is now powered by electric motor,any copper gaskets were always annealed he would heat these to a dull red and dunk them in a tub of water they were then nice and soft just like new. Keith.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Re: Cutting Gaskets

Re: Cutting Gaskets

For the holes I use an old small screwdriver with the end ground down to form a sharp pin prick and go around the hole with that, the material then just pushes out.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Cutting Gaskets

Re: Cutting Gaskets

QUOTE "I'm going with the thinnest one of the lot, literally paper thin."

Remember that on some engines the thickness of the gasket controls the crank and camshaft end float.

Too thin a gasket could leave you wondering why the engine is stiff to turn after reassembly.

No Engineer's Blue or black grease? Black shoe polish might do.

Remember that on some engines the thickness of the gasket controls the crank and camshaft end float.

Too thin a gasket could leave you wondering why the engine is stiff to turn after reassembly.

No Engineer's Blue or black grease? Black shoe polish might do.

wristpin- I really need to post more

- Posts : 7

Join date : 2013-03-31

Location : Romney Marsh, Kent

Re: Cutting Gaskets

Re: Cutting Gaskets

I dropped lucky a few months ago, one of the old boys at work retired and dumped a lot of stuff from his toolbox that he wouldn't use at home, it included about a dozen hole punches/wad cutters in various sizes which I saved from the scrap bin.

Stuart.

Stuart.

Robotstar5- Life Member

- Posts : 1110

Join date : 2018-09-25

Re: Cutting Gaskets

Re: Cutting Gaskets

Hi Robotstar5,

Sounds like santa came early for you when your workmate dumped his unwanted tooling,The hole punches are easy enough to make if you have a lathe and if you make them out of silversteel you can harden and temper them.

Regards,

Chiefy.

Sounds like santa came early for you when your workmate dumped his unwanted tooling,The hole punches are easy enough to make if you have a lathe and if you make them out of silversteel you can harden and temper them.

Regards,

Chiefy.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Re: Cutting Gaskets

Re: Cutting Gaskets

chiefy wrote:

The hole punches are easy enough to make if you have a lathe....

Regards,

Chiefy.

Yeah - I wish.

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2818

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Cutting Gaskets

Re: Cutting Gaskets

chiefy wrote:Hi Robotstar5,

....The hole punches are easy enough to make if you have a lathe and if you make them out of silversteel you can harden and temper them.

Regards,

Chiefy.

Sadly I don't have a lathe and the last time I used one was in the 70's in the first year of my apprenticeship.

Stuart.

Robotstar5- Life Member

- Posts : 1110

Join date : 2018-09-25

Re: Cutting Gaskets

Re: Cutting Gaskets

Hi Robotstar5,

Buy yourself a lathe and if you can a milling machine too,you will never regret it, i have 2 a Harrison L5 and a Drummond flat bed made in 1905 this was fathers lathe it was originally a foot treadled lathe as we did not have electricity until after the war,it now runs off electric now.

Regards,

Chiefy.

Buy yourself a lathe and if you can a milling machine too,you will never regret it, i have 2 a Harrison L5 and a Drummond flat bed made in 1905 this was fathers lathe it was originally a foot treadled lathe as we did not have electricity until after the war,it now runs off electric now.

Regards,

Chiefy.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Re: Cutting Gaskets

Re: Cutting Gaskets

The simplest way of making parallel hole punches is to use an old steel shafted golf club.

The problem with using wadding punches is they are designed to produce parallel plugs but leave tapered holes.

This isn't such a problem with thinner gasket material but when used on thick, soft stuff the holes become more like craters.

Golf clubs are a ready source of thin walled high carbon steel that will sharpen (internally) to give a keen edge and parallel outside. Most clubs o/d. is between 9 and 14mm in a number of steps so it's a matter of cutting a length at the desired diameter.

Keep up the good work,

Mike.

The problem with using wadding punches is they are designed to produce parallel plugs but leave tapered holes.

This isn't such a problem with thinner gasket material but when used on thick, soft stuff the holes become more like craters.

Golf clubs are a ready source of thin walled high carbon steel that will sharpen (internally) to give a keen edge and parallel outside. Most clubs o/d. is between 9 and 14mm in a number of steps so it's a matter of cutting a length at the desired diameter.

Keep up the good work,

Mike.

mikep- Expert

- Posts : 69

Join date : 2024-03-20

Location : Gosport

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Valve seat cutting.

» Head Gaskets Again

» Lister D Gaskets

» BSA 420 POWER UNIT GASKETS

» copper head gaskets

» Head Gaskets Again

» Lister D Gaskets

» BSA 420 POWER UNIT GASKETS

» copper head gaskets

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum