Very old Briggs and Stratton

+6

matt86

hob

pauldg

kevjhnsn

mike d

Foden

10 posters

Page 3 of 5

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Well, we tried all sorts. I had a rainy day off today so after painting the bathroom ceiling I decided to set the slide hammer up on the shaft extension, the pullers supplied don't reach so I got a shackle round the shaft and attached some chain to it and to the slide hammer's 2legged puller attachment (sorry, was too busy to get pics).

The engine was laid on it's side with the shaft hanging through the workmate. I tried it with heat and without heat, banging and banging away until I couldn't feel my fingers! Then I chucked the whole set-up, workmate and all, in my car and set off for a second and third opinion.

We tried the same thing again in a better equipped workshop with more heat from a better blowtorch. Wouldn't budge! We tried banging the shaft extension back on just to get it moving, it moved (albeit in the wrong direction) then tried the heat and slide hammer again and it wouldn't move at all ! Then I got fed up and we attacked it with the angle grinder.

! Then I got fed up and we attacked it with the angle grinder.

After much grinding and a bit of cold chiselling we got it off. I may have nicked the shaft a bit with the grinder but it's not serious and a new pulley will cover it up. At least I can get the crankshaft out now, check the bearings and clean and paint all over the engine.

Will try to get some pictures up soon, it's sitting in my car at the moment.

The engine was laid on it's side with the shaft hanging through the workmate. I tried it with heat and without heat, banging and banging away until I couldn't feel my fingers! Then I chucked the whole set-up, workmate and all, in my car and set off for a second and third opinion.

We tried the same thing again in a better equipped workshop with more heat from a better blowtorch. Wouldn't budge! We tried banging the shaft extension back on just to get it moving, it moved (albeit in the wrong direction) then tried the heat and slide hammer again and it wouldn't move at all

After much grinding and a bit of cold chiselling we got it off. I may have nicked the shaft a bit with the grinder but it's not serious and a new pulley will cover it up. At least I can get the crankshaft out now, check the bearings and clean and paint all over the engine.

Will try to get some pictures up soon, it's sitting in my car at the moment.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Damn thing wasn't budging, was it? I don't see we had much choice.

Anyway, if I remember correctly it wasn't running true, that shaft extension, & it didn't look right in my humble opinion. We'll have to get Stu to keep a look out for a nice flat belt pulley for us, a big long one to cover up the shaft & give us plenty of options on belts.

If you measure the shaft size & put up a wanted ad something's bound to turn up. Was it a 1" shaft??? I would say something like a 4" diameter pulley would be a good one to go for, like you see on most Lister D's & Petter A1's.

At least it's off now & we can move on. It won't be long now 'til she's up & running once more.

Anyway, if I remember correctly it wasn't running true, that shaft extension, & it didn't look right in my humble opinion. We'll have to get Stu to keep a look out for a nice flat belt pulley for us, a big long one to cover up the shaft & give us plenty of options on belts.

If you measure the shaft size & put up a wanted ad something's bound to turn up. Was it a 1" shaft??? I would say something like a 4" diameter pulley would be a good one to go for, like you see on most Lister D's & Petter A1's.

At least it's off now & we can move on. It won't be long now 'til she's up & running once more.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Yep, 1" shaft. 4" flat belt pulley would be very nice but I'll put a V belt on it if I have to.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

One shaft extension, in two pieces....

Now in my metal scraps bin

Now in my metal scraps bin

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Something fight till the very end.

Your able to move on now so fingers crossed the bearings are all ok.

Your able to move on now so fingers crossed the bearings are all ok.

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

It would seem that this engine is, very gradually, migrating its' way over to my workshop (OK, so it's really my dad's workshop, but YKWIM).

So far I've restored the carb, restored the magneto, & restored the 2 cowling back-plates. The carb managed to make it back over to Ian's place, but I guess it will soon be back over here.

Today Ian turned up with the 2 cowlings for me to "work my magic" on. I think we're both coming to the realisation that, what with family commitments & work, Ian just hasn't got the time to spend on this engine. Also, after christmas, he will need to help the boys with their Lister D project.

So, it's kind of been agreed that the Briggs can come over here & I will finish it off. But, before the main lump can come over, we need to make some space. This means finishing off some other projects & moving them over to Ian's garage, unless space can be comfortably found over here (which, since the arrival of the Scott, is very unlikely). He might be able to fit some in as it is, but really we need a bloody good sort out in his garage, so that we can store stuff & he can still work on stuff as well.

Anyway, I've started work on the cowlings tonight. I've given them the once over with the drill powered wire brush & left them with a smear of paint stripper, so they should end up back to bare metal over the next few days.

I'll see how bad the rust pitting looks when they're stripped, but I think we're going to need some build-up primer or some thin filler or something, as they look quite badly pitted.

Will see what I can do with regards to pictures.

So far I've restored the carb, restored the magneto, & restored the 2 cowling back-plates. The carb managed to make it back over to Ian's place, but I guess it will soon be back over here.

Today Ian turned up with the 2 cowlings for me to "work my magic" on. I think we're both coming to the realisation that, what with family commitments & work, Ian just hasn't got the time to spend on this engine. Also, after christmas, he will need to help the boys with their Lister D project.

So, it's kind of been agreed that the Briggs can come over here & I will finish it off. But, before the main lump can come over, we need to make some space. This means finishing off some other projects & moving them over to Ian's garage, unless space can be comfortably found over here (which, since the arrival of the Scott, is very unlikely). He might be able to fit some in as it is, but really we need a bloody good sort out in his garage, so that we can store stuff & he can still work on stuff as well.

Anyway, I've started work on the cowlings tonight. I've given them the once over with the drill powered wire brush & left them with a smear of paint stripper, so they should end up back to bare metal over the next few days.

I'll see how bad the rust pitting looks when they're stripped, but I think we're going to need some build-up primer or some thin filler or something, as they look quite badly pitted.

Will see what I can do with regards to pictures.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

It would be good to see it running for next season, especially as it is so easy to lug about but still powerful enough to run a fair few things.

Time and space are big problems for me at the moment, plus I should make use of my brother and his talents while I can, keeps him out of trouble

Time and space are big problems for me at the moment, plus I should make use of my brother and his talents while I can, keeps him out of trouble

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I think the dark nights have a lot to do with it, Ian I'm sure by the time you get in from work have half an hour with the kids get your dinner then the last thing you'll want to do is go outside and work in a cold garage. Good idea to pass it over to Nuts, keep him busy and out of mischief as when he has nothing to do he just starts to dismantle things to see how they work.

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Right, I finally got my hands on the rest of this engine on Sunday, so I decided to make a start on it today.

So far I've taken the cam shaft out (not an easy job), cleaned out the crank case & sump, cleaned off all the old paint & crud from the outsides of the crank case & sump, with the drill-wire brush. I've also cleaned the cam shaft, cleaned the tappets, cleaned loads of other bits & started to put it back together.

I've had the oil pump apart & cleaned that all out as well.

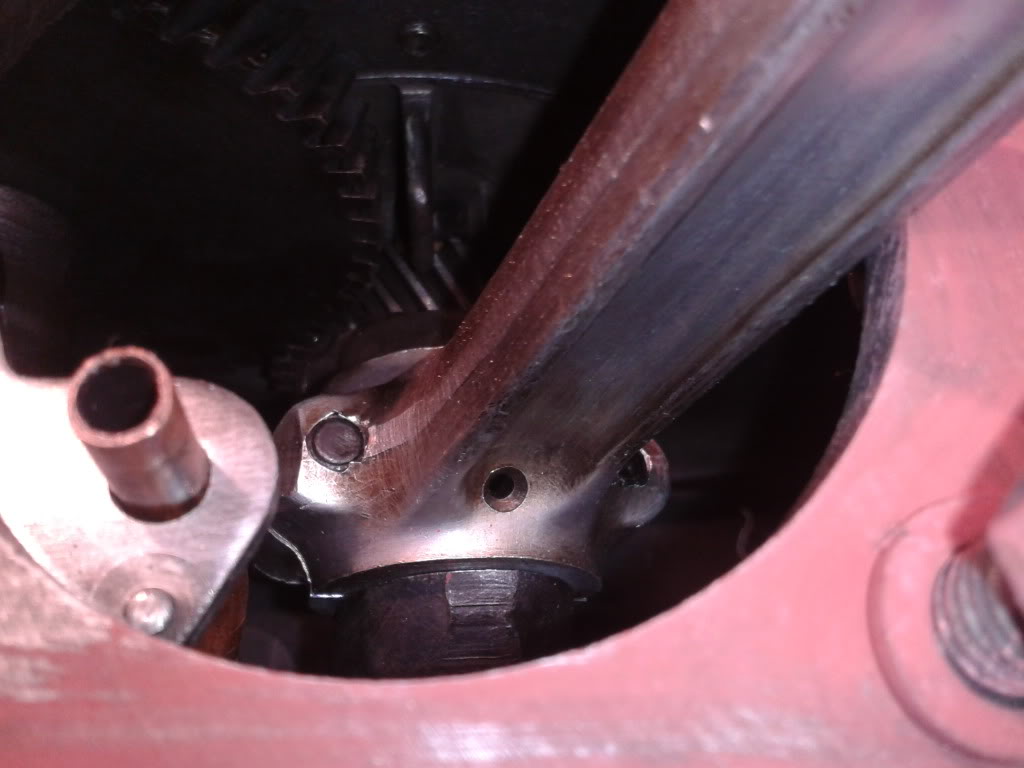

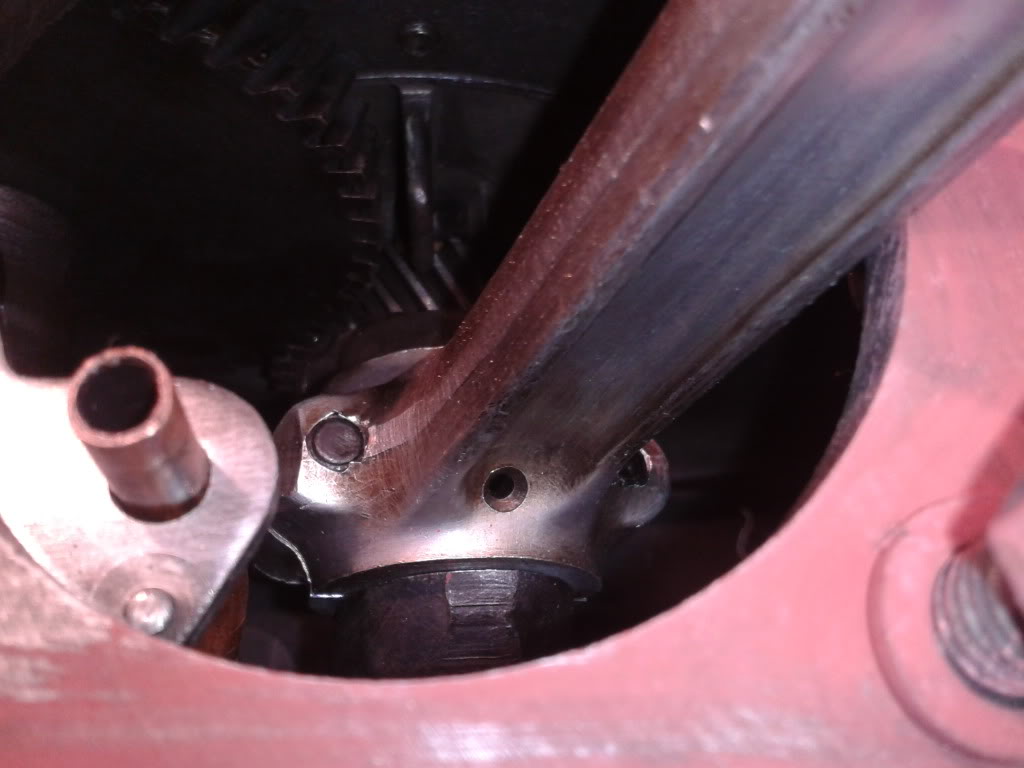

I've even got the paint brushes out & given it a coat of primer in places. here's a few pics (please note the engine is upside down in all these pics)....

Here's a few shots of it going back together after cleaning....

Here's some of the bits cleaned up ready to go back in, & a few of the last bits which need cleaning, soaking in my patent parts wash solution (even I don't know what's in it!)....

& here it is as I left it tonight....

Tomorrow I will continue cleaning the parts & continue to rebuild the engine. Can't see any problems just yet, but obviously we still have no fuel tank mountings sorted out yet. But don't forget both the carb & the magneto have been restored & re-built, the cowling backplates have been stripped, prepped, primed & painted & both of the cowlings & the fuel tank have also been stripped, prepped & primed, & have their first top coat, just waiting for a rub down & final top coat.

So, much of the hard work has been done. The only bits I haven't touched yet are the flywheels. Which I hope to attack tomorrow, along with the last few internals. The head & barrel are going to be the hardest bit as I don't have a sand blaster & the exhaust silencer is still attached & refuses to budge. As it's an original exhaust I don't want to risk any damage.

Still, engine first. I will worry about the head, barrel & exhaust when they come along.

So far I've taken the cam shaft out (not an easy job), cleaned out the crank case & sump, cleaned off all the old paint & crud from the outsides of the crank case & sump, with the drill-wire brush. I've also cleaned the cam shaft, cleaned the tappets, cleaned loads of other bits & started to put it back together.

I've had the oil pump apart & cleaned that all out as well.

I've even got the paint brushes out & given it a coat of primer in places. here's a few pics (please note the engine is upside down in all these pics)....

Here's a few shots of it going back together after cleaning....

Here's some of the bits cleaned up ready to go back in, & a few of the last bits which need cleaning, soaking in my patent parts wash solution (even I don't know what's in it!)....

& here it is as I left it tonight....

Tomorrow I will continue cleaning the parts & continue to rebuild the engine. Can't see any problems just yet, but obviously we still have no fuel tank mountings sorted out yet. But don't forget both the carb & the magneto have been restored & re-built, the cowling backplates have been stripped, prepped, primed & painted & both of the cowlings & the fuel tank have also been stripped, prepped & primed, & have their first top coat, just waiting for a rub down & final top coat.

So, much of the hard work has been done. The only bits I haven't touched yet are the flywheels. Which I hope to attack tomorrow, along with the last few internals. The head & barrel are going to be the hardest bit as I don't have a sand blaster & the exhaust silencer is still attached & refuses to budge. As it's an original exhaust I don't want to risk any damage.

Still, engine first. I will worry about the head, barrel & exhaust when they come along.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Looks like you are reassembling the oil pump in a strange way, I'll post you a link to the instructions when I get home or you can check my thread on smokstak. Otherwise its looking very good.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Ianhw77k wrote:Looks like you are reassembling the oil pump in a strange way, I'll post you a link to the instructions when I get home or you can check my thread on smokstak. Otherwise its looking very good.

Nothing different to the picture, I just haven't fitted the outlet tube yet, but it will go on easy enough.

The sump will probably have to come off again anyway to do the big end, I just wanted it on there to protect the oil pump & keep it clean.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Today I've been having trouble with a damaged oil seal, well it's more of a scraper ring really, it looks to have been damaged by trying to remove that shaft extension, I've tried to re-shape it but really it needs a new one. However, I am informed this could be very difficult, so I may just have to mend & make do. Anyway, here's the story from today's tinkerings....

Right, today I did some more. I decided it was time to get the crank shaft & governor gear back in the crank case, get the oil pump properly installed & get the sump back on for good.

In order to get the crank shaft in & timed I had to put the magneto backplate back on, so I thought I would grab a few more bits & bobs & have a little play at building her up (after all it wasn't me who disassembled this engine & I need to know where all the nuts & bolts go)....

Then I set about re-attaching the mag backplate to the cowling backplate on that side. It was previously attached by 4 brass rivets which I had to drill out, so I tapped the holes M4, drilled & countersunk the cowl backplate holes to M4 clearance, screwed it all together & cut the screw ends off....

I've done a few other little jobs, like soldering on the new stop button wire, & given the whole thing another coat of red oxide primer. I also attached the con-rod (there's a tiny bit of big-end play, but nothing significant & the bearings didn't look badly scored) but mainly I've been trying to put some order to this restoration.

For instance I need to prime all the cowling screws & work out in which order to paint everything. The cowlings & petrol tank already have their first top coat, & these bits will receive a good rub down before a final top coat (it's Rustoleum paint, so it wouldn't matter if, during this final rub down, any metal was uncovered, I've mainly used the 3 or 4 layers of primer to cover up all the rust pitting) but the question is; when to do this final rub down & top coat?

So, the crank case will need another coat of primer, then when it's fully hardened (a day or 2) it will be rubbed down & inspected. It may then get another primer coat before it's top coat, either way it needs a top coat before the cowling backplates can go on, then the flywheels & head & barrel need to go back on before the cowlings can go back. Then I will give everything I can see the final rub down & top coat, as there's no point going to town on bits that won't be seen, especially as everything will have a good protective coating anyway.

Finally, here's some pictures & explanations of those oil seals. here's the 2 crank shaft oil scraper rings (they're not actually seals, the white metal coated main bushes act pretty much as seals, these just direct any escaping oil back into the sump)....

Inner face (I think)....

Outer face....

& one in one out....

Here's a shot of where they sit....

& here's one in place, as I think they should go....

& here it is in what I believe to be the wrong position....

Any thoughts?

Next big job will be cleaning the head & barrel. Not looking forward to that one, but in the meantime, here's the final few bits for me to parts wash....

Oh yes, & I almost forgot, can anyone tell me if I got the con rod back in the right way round? there's an oil hole in one side to feed the big end bearing....

I'm guessing this hole goes on the same side as the delivery tube from the oil pump, like so....

Can anyone tell me if this is correct?

Right, today I did some more. I decided it was time to get the crank shaft & governor gear back in the crank case, get the oil pump properly installed & get the sump back on for good.

In order to get the crank shaft in & timed I had to put the magneto backplate back on, so I thought I would grab a few more bits & bobs & have a little play at building her up (after all it wasn't me who disassembled this engine & I need to know where all the nuts & bolts go)....

Then I set about re-attaching the mag backplate to the cowling backplate on that side. It was previously attached by 4 brass rivets which I had to drill out, so I tapped the holes M4, drilled & countersunk the cowl backplate holes to M4 clearance, screwed it all together & cut the screw ends off....

I've done a few other little jobs, like soldering on the new stop button wire, & given the whole thing another coat of red oxide primer. I also attached the con-rod (there's a tiny bit of big-end play, but nothing significant & the bearings didn't look badly scored) but mainly I've been trying to put some order to this restoration.

For instance I need to prime all the cowling screws & work out in which order to paint everything. The cowlings & petrol tank already have their first top coat, & these bits will receive a good rub down before a final top coat (it's Rustoleum paint, so it wouldn't matter if, during this final rub down, any metal was uncovered, I've mainly used the 3 or 4 layers of primer to cover up all the rust pitting) but the question is; when to do this final rub down & top coat?

So, the crank case will need another coat of primer, then when it's fully hardened (a day or 2) it will be rubbed down & inspected. It may then get another primer coat before it's top coat, either way it needs a top coat before the cowling backplates can go on, then the flywheels & head & barrel need to go back on before the cowlings can go back. Then I will give everything I can see the final rub down & top coat, as there's no point going to town on bits that won't be seen, especially as everything will have a good protective coating anyway.

Finally, here's some pictures & explanations of those oil seals. here's the 2 crank shaft oil scraper rings (they're not actually seals, the white metal coated main bushes act pretty much as seals, these just direct any escaping oil back into the sump)....

Inner face (I think)....

Outer face....

& one in one out....

Here's a shot of where they sit....

& here's one in place, as I think they should go....

& here it is in what I believe to be the wrong position....

Any thoughts?

Next big job will be cleaning the head & barrel. Not looking forward to that one, but in the meantime, here's the final few bits for me to parts wash....

Oh yes, & I almost forgot, can anyone tell me if I got the con rod back in the right way round? there's an oil hole in one side to feed the big end bearing....

I'm guessing this hole goes on the same side as the delivery tube from the oil pump, like so....

Can anyone tell me if this is correct?

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

It's difficult to say looking at just the pics. Will it make much difference if it is fitted the wrong way round? The oil seals I would say goes in like 1st picture but if you look at the crank has it any running marks? Once you find out which way they go put the worst damaged part top the top and maybe smear it with some kind of instant gasket. I wonder if you'd get any benifit by putting a smear around the inside of the the seal just to make a better seal.

As for the con rod can you not tell by the way the piston fits?

Stu.

As for the con rod can you not tell by the way the piston fits?

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Someone on SmokStak has answered my con-rod query, apparently I had it the right way round. As for the oil seal, I had much the same idea as you Stu, put the most mis-shapen bit towards the top. I've managed to knock it into shape now & it's not such a bad fit. I don't think I will use any instant gasket, as I don't want to risk any getting into the oil hole.

So, now it's full steam ahead. I've had a little play with the magneto today & I'm getting a good spark at surprisingly low turning speeds, which is very good news.

So, now it's full steam ahead. I've had a little play with the magneto today & I'm getting a good spark at surprisingly low turning speeds, which is very good news.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I did mean just a smear and then let it cure and maybe trim off any excess but as you've straightened it out a bit more it maybe ok now.

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

HT lead & plug terminal turned up today, I will be getting on with this one this afternoon, try to get it finished by the end of the week (although I doubt the tank will be on by then).

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I took the head and barrel back to mine today as I had a brainwave and wanted to see if it would be effective.

Basically I have a small Karcher pressure washer and I thought this might just work for blasting away some of the crud from in between the fins.

It didn't take long and I think there was a definite improvement, check out the pictures.

Obviously there will be more work to do but I got a lot of the crud out from there and the barrel itself should be about ready for it's Kurust treatment although I may just run a wire brush over them in the morning to chip away at the last of the loose rust. The head may have to be painted with some high temp silver but that's nothing new, all the ally on this engine seems to be past the stage of polishing and has needed painting.

Basically I have a small Karcher pressure washer and I thought this might just work for blasting away some of the crud from in between the fins.

It didn't take long and I think there was a definite improvement, check out the pictures.

Obviously there will be more work to do but I got a lot of the crud out from there and the barrel itself should be about ready for it's Kurust treatment although I may just run a wire brush over them in the morning to chip away at the last of the loose rust. The head may have to be painted with some high temp silver but that's nothing new, all the ally on this engine seems to be past the stage of polishing and has needed painting.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Good work Ian, now do it again & this time do it properly!

Anyway, I did absolutely nothing with this engine today, got very much sidetracked by the Kohler.

The barrel looks good, buy I wonder if we shouldn't tackle the head again with some of that Swarfega drive cleaner. I just fon't know how I'm going to polish it up & I'd rather not paint it.

Anyway, I did absolutely nothing with this engine today, got very much sidetracked by the Kohler.

The barrel looks good, buy I wonder if we shouldn't tackle the head again with some of that Swarfega drive cleaner. I just fon't know how I'm going to polish it up & I'd rather not paint it.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

There's only acid that I know will clean aluminium but can't remember which one, I think it's sulphuric but you need to be very careflly when using it as I don't think it's 100% pure.

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

stationary stu wrote:There's only acid that I know will clean aluminium but can't remember which one, I think it's sulphuric but you need to be very careflly when using it as I don't think it's 100% pure.

Stu.

Hmm, I'll have to look into that one Stu, I have got some acidic rust remover stuff, that might be worth a try.

Anyway, Ian has washed the head & barrel back at his place with a pressure washer, I've just got it back, it'll still need a few of the stubborn bits scraping off, but it's much better than it was. I don't want to paint the head silver, I would rather it was polished aluminium, but I'm not so sure it will polish up.

Anyway, today I did some painting, I started with the red detailing bits on the starter pulley & the oil filler & drain plugs, then the silver on the flywheels....

Then the black came out & I gave the crank case a coat, as well as the insides of the cowlings, that's pretty much everything painted now, just the head & barrel to go, but that'll be Kurust for the barrel & not sure what to do with the head yet....

Oh yes, & I've still got the breather standpipe & filter thingy to clean up & paint. I have taken it apart for cleaning & inside the filter part were 2 metal strainers with what I thought was wire wool between them. I took out this stuff & soaked it in my parts wash solution. Last night I decided to remove it, rinse it & dry it as best as I could, but it's started to fall apart.

It turns out it's not wire wool, it's almost like hay or some kind of plant fibres. It's falling to bits anyway & there's no way I'm putting it back in there as most of it will end up in the sump. So, can anyone tell me what it is (or was)....

I'm not sure what to put in there now, I would rather not use wire wool, so I might go for some Scotchbrite type pads or something else, maybe rockwool insulation???

Any thoughts?

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Nuts I know your a big user of Rust-o-leum but is it really as good as they say

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

stationary stu wrote:Nuts I know your a big user of Rust-o-leum but is it really as good as they say

Stu.

TBH Stu, I'm going off it on price grounds. It beats the sh1t out of Hammerite, but it's cheaper to buy a good primer & some machine enamel to go on top. OK it takes more coats, & therefore more time, but it works out cheaper & the finish is just as durable.

the trouble with all these one coat/self undercoating paints is they are too thick. I found Rustoleum was at it's best when I thinned it down with white spirit, but then it needed 2 coats, same as your average tractor/machine enamel.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I had a similar problem with Hammerite, it was just to thick to paint on and get a good finish, in fact it was the worst paint finish I'd seen.

The good point about Rustoleum is it helps keep rust at bay so it might be a case of a coat of kurust or similar. I'm thinking of getting something like this (below) and paint it of first before I put a good primer on. I always use enamel paint, there all the same, some say that coach enamel is better then machine enamel well the truth is there's no difference it just depends what the manufacturer labels it.

http://www.ebay.co.uk/itm/260521454714?ssPageName=STRK:MEWAX:IT&_trksid=p3984.m1423.l2649

Stu.

The good point about Rustoleum is it helps keep rust at bay so it might be a case of a coat of kurust or similar. I'm thinking of getting something like this (below) and paint it of first before I put a good primer on. I always use enamel paint, there all the same, some say that coach enamel is better then machine enamel well the truth is there's no difference it just depends what the manufacturer labels it.

http://www.ebay.co.uk/itm/260521454714?ssPageName=STRK:MEWAX:IT&_trksid=p3984.m1423.l2649

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Yeah, Rustoleum is much better than Hammerite, much more like normal paint, & it's pretty petrol proof when it's gone off properly. It's very good stuff, but about twice the price of normal machine/tractor enamel.

I spent the entire afternoon sorting out & cleaning up the workshop. Now we can actually move in there I can get on with this one.

Before I started on that though I put the cowling backplates on & turned the engine upside down. I've painted the underneath of the sump, & painted the last bit of the dummy flywheel, which I couldn't do yesterday as it was sitting on it.

I've just been out there, righted the engine (the paint's still a bit tacky on the underside, so I put it on some bits of batten, it's not like it will ever be seen & this bit was never painted originally anyway). Then I put the 2 flywheels back on. They look good in their silver paint.

Next I will give the few red bits their 2nd coat, then I will scrape off the last few bits of stubborn muck from the barrel, ready for a coat of Kurust tomorrow (or maybe tonight, see how I get on).

Once the barrel's coated & dry it can go back on. I've got to cut a new gasket for the base, then scrape some of the paint & primer off the top of the crank case where the barrel goes back on (I just painted roughly where I thought it would go).

I may well be ready for a start-up on Thursday, possibly Wednesday (although I'm under strict instructions not to start it until my brother is there & he can't make it until Thursday).

Still, plenty of little bits to do in the meantime.

I spent the entire afternoon sorting out & cleaning up the workshop. Now we can actually move in there I can get on with this one.

Before I started on that though I put the cowling backplates on & turned the engine upside down. I've painted the underneath of the sump, & painted the last bit of the dummy flywheel, which I couldn't do yesterday as it was sitting on it.

I've just been out there, righted the engine (the paint's still a bit tacky on the underside, so I put it on some bits of batten, it's not like it will ever be seen & this bit was never painted originally anyway). Then I put the 2 flywheels back on. They look good in their silver paint.

Next I will give the few red bits their 2nd coat, then I will scrape off the last few bits of stubborn muck from the barrel, ready for a coat of Kurust tomorrow (or maybe tonight, see how I get on).

Once the barrel's coated & dry it can go back on. I've got to cut a new gasket for the base, then scrape some of the paint & primer off the top of the crank case where the barrel goes back on (I just painted roughly where I thought it would go).

I may well be ready for a start-up on Thursday, possibly Wednesday (although I'm under strict instructions not to start it until my brother is there & he can't make it until Thursday).

Still, plenty of little bits to do in the meantime.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Here we go with some pics of tonight's exploits....

Flywheels back on....

Barrel, plus a few other bits coated with Kurust (I will have to give them a coat of high temp black as well, as there is old paint there I can't get to & the Kurust won't take to that)....

I also put the governor arm back on, made up a new throttle linkage (I snapped the old one getting it off the governor arm) & put the old (rather "home made" looking) governor spring back on....

Then I cut a new base gasket (using my tried & trusted method of coating the base in black grease to make an impression)....

& to top it all off I painted the stop button red....

I guess tomorrow I should paint the barrel, clean the head up & cut myself a new head gasket from some 1.5mm Tesnit (actually, it might be 2mm, can't remember now). I've looked at the old head gasket & it's just no good, it needs a new one. If anyone knows if/where I can get a proper one from then I would love to know.

I think the head is definitely beyond polishing, but I will have a go anyway.

I also de-coked the ports & cleaned up the area where the valve springs sit. So, it's all coming along really well. At this rate I'll have it running tomorrow! I will have to go out & get some fuel & some oil first though. (I probably won't have it running tomorrow).

As this one has been completely rebuilt & every trace of old oil has been removed & all the internals completely cleaned, I will be using a multigrade oil. I use a very basic (cheap) 20w50 oil (Comma Motorway), I don't think it contains any detergents (although may of these so called "Classic" oils still do) but if it does it will be very low levels, it's just a basic, mineral based, motor oil, & perfect for this engine. I will need to test the oil pump before the barrel goes back on as well (mustn't forget that job).

Flywheels back on....

Barrel, plus a few other bits coated with Kurust (I will have to give them a coat of high temp black as well, as there is old paint there I can't get to & the Kurust won't take to that)....

I also put the governor arm back on, made up a new throttle linkage (I snapped the old one getting it off the governor arm) & put the old (rather "home made" looking) governor spring back on....

Then I cut a new base gasket (using my tried & trusted method of coating the base in black grease to make an impression)....

& to top it all off I painted the stop button red....

I guess tomorrow I should paint the barrel, clean the head up & cut myself a new head gasket from some 1.5mm Tesnit (actually, it might be 2mm, can't remember now). I've looked at the old head gasket & it's just no good, it needs a new one. If anyone knows if/where I can get a proper one from then I would love to know.

I think the head is definitely beyond polishing, but I will have a go anyway.

I also de-coked the ports & cleaned up the area where the valve springs sit. So, it's all coming along really well. At this rate I'll have it running tomorrow! I will have to go out & get some fuel & some oil first though. (I probably won't have it running tomorrow).

As this one has been completely rebuilt & every trace of old oil has been removed & all the internals completely cleaned, I will be using a multigrade oil. I use a very basic (cheap) 20w50 oil (Comma Motorway), I don't think it contains any detergents (although may of these so called "Classic" oils still do) but if it does it will be very low levels, it's just a basic, mineral based, motor oil, & perfect for this engine. I will need to test the oil pump before the barrel goes back on as well (mustn't forget that job).

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Page 3 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» 9hp Briggs & Stratton

» Briggs & stratton

» Another Briggs & Stratton

» 2hp Briggs & Stratton

» 1970 Briggs & Stratton 9hp

» Briggs & stratton

» Another Briggs & Stratton

» 2hp Briggs & Stratton

» 1970 Briggs & Stratton 9hp

Page 3 of 5

Permissions in this forum:

You cannot reply to topics in this forum