Very old Briggs and Stratton

+6

matt86

hob

pauldg

kevjhnsn

mike d

Foden

10 posters

Page 2 of 5

Page 2 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Apparently I was wrong (it does happen  ) there is an oil pump, it's driven off the cam shaft, all internal with a metal gauze filter and it squirts oil up into the piston on the down stroke as far as I can tell. I have been shown a document telling you how to remove it, test it and replace it. It was the same on the Z models.

) there is an oil pump, it's driven off the cam shaft, all internal with a metal gauze filter and it squirts oil up into the piston on the down stroke as far as I can tell. I have been shown a document telling you how to remove it, test it and replace it. It was the same on the Z models.

Its nice to get cracking on it again, I was involving the kids with it as well although they got bored after a while and started playing musical instruments with my spanners

I'll see if I can get any decent pictures for you guys today.

Its nice to get cracking on it again, I was involving the kids with it as well although they got bored after a while and started playing musical instruments with my spanners

I'll see if I can get any decent pictures for you guys today.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Here we go. I have just been down there trying to get the gudgeon pin out but the bugger won't shift and I don't want to crack an 81 year old ally piston!

While doing this I suddenly noticed a single valve collet sitting beside one of the pushrods, this freaked me out somewhat as I thought maybe it had popped out while I was removing the barrel last night so I panicked looking for it's partner, then checked the valves and they all seem to be OK. It looks like someone has done some work on them at one time so maybe they dropped a collet down there and just left it . One of the valves doesn't even look like it had collets, it has a pin through it holding the spring on. Very confusing but if it works I'll leave it. See what you think from the pictures.

. One of the valves doesn't even look like it had collets, it has a pin through it holding the spring on. Very confusing but if it works I'll leave it. See what you think from the pictures.

Valve stuff

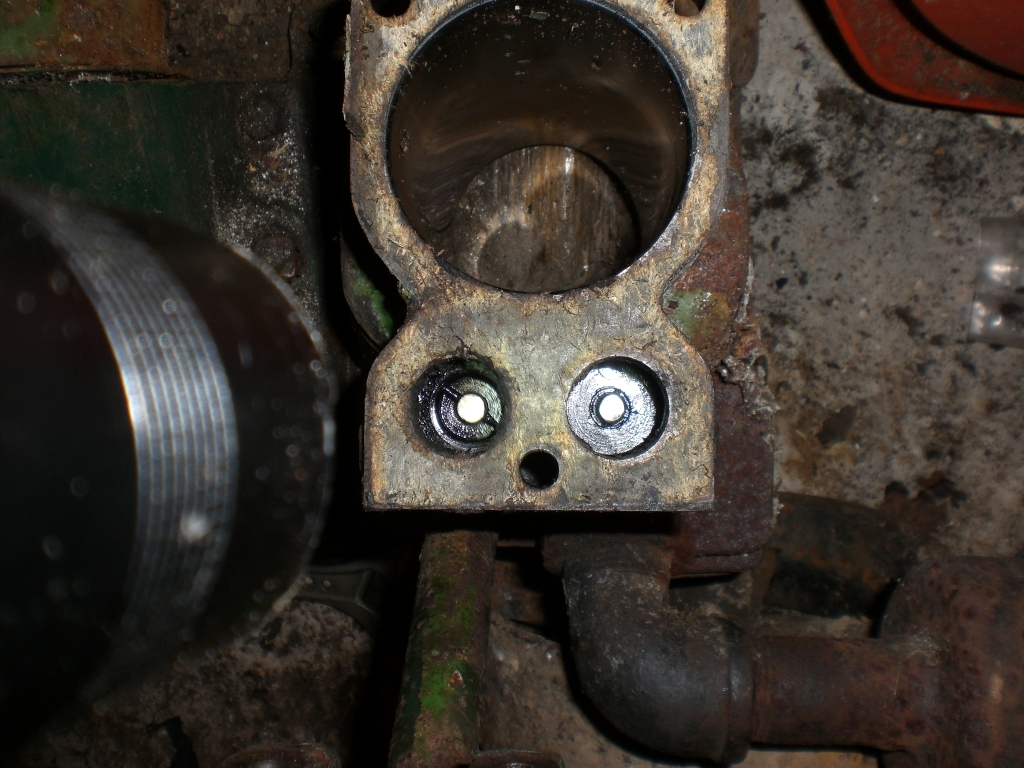

Piston scoring (the worst bit, nothing major though I reckon. Looks like the engine has been run a bit dry at some point)

The oiling tube that runs directly from the pump

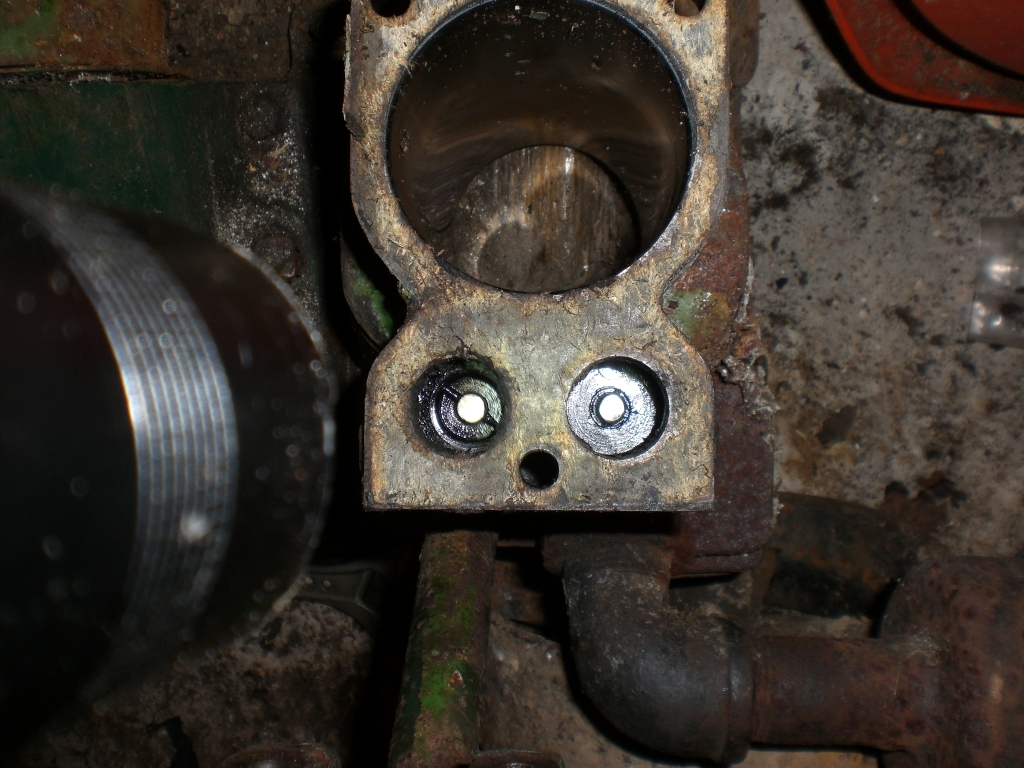

The crank webs and block

Finally, the resident toad in my garage that has taken a real liking to this engine

While doing this I suddenly noticed a single valve collet sitting beside one of the pushrods, this freaked me out somewhat as I thought maybe it had popped out while I was removing the barrel last night so I panicked looking for it's partner, then checked the valves and they all seem to be OK. It looks like someone has done some work on them at one time so maybe they dropped a collet down there and just left it

Valve stuff

Piston scoring (the worst bit, nothing major though I reckon. Looks like the engine has been run a bit dry at some point)

The oiling tube that runs directly from the pump

The crank webs and block

Finally, the resident toad in my garage that has taken a real liking to this engine

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Thanks for posting the pics, normally it's someone with lots of spares like the engines agent that when dropping a collect would just get another not look for the old one so it must of had some work done on the engine in the past, that's possibly why it looks so good today.

About the toad in the garage it's not that un-common, when I worked in a garage we had a few vehicles towed in....

Keep up the good work,

Stu.

About the toad in the garage it's not that un-common, when I worked in a garage we had a few vehicles towed in....

Keep up the good work,

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

That's exactly what I thought Stu, it must have rattled out of the crud surrounding the push rod when I was trying to remove the gudgeon pin, probably why it looked so fresh. I'll whip the valves out soon and see what the seats look like.

I think I may have to leave the piston where it is, I'm pretty sure there is no play in the top end anyway. I'll split the big end and get the whole lot out that way, then I really want to get the other flywheel off the other side but it isn't looking like an easy job. Patience, easing oil, heat, pullers and a lot of perseverance is called for I think. I'll show you what I'm up against:

I think I may have to leave the piston where it is, I'm pretty sure there is no play in the top end anyway. I'll split the big end and get the whole lot out that way, then I really want to get the other flywheel off the other side but it isn't looking like an easy job. Patience, easing oil, heat, pullers and a lot of perseverance is called for I think. I'll show you what I'm up against:

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

That doesn't look like it's been removed since the engine was built, I think it's going to be a long slow job to get it moving so good luck and take your time, I'm sure you must have more patents then your brother

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

OK, I was in the garage today (wangled a 4 day weekend somehow  ) sorting out the tools I've been accumulating at rallies and jumble sales lately and eventually getting my hedge trimmer to work reliably (I hope). Then I decided to turn my attention to the briggs, not expecting to get much done I actually spent quite a few hours getting really stuck into it.

) sorting out the tools I've been accumulating at rallies and jumble sales lately and eventually getting my hedge trimmer to work reliably (I hope). Then I decided to turn my attention to the briggs, not expecting to get much done I actually spent quite a few hours getting really stuck into it.

I cut/kicked the old rotten wooden trolley off it and had to hacksaw off the mounting bolts (don't worry, they were only cheapo metric things). Then I decided to remove the sump/baseplate. Inside I found the oil pump and removed that. I managed to get the pulley off on Friday when I was supposed to be packing the car for the rally.

Then I undid the big end to remove the piston and con-rod. Of course, I emptied the oil before doing any of this.

Then I could rest the piston on the workmate I am using as a bench and get the gudgeon pin out. Christ only knows how I'm going to get it back in, it is a really tight fit.

I am now stuck on the last flywheel and what I now think is a shaft extension. Like I said, I removed the pulley, it came off relatively easily with a three legged puller but a puller will be useless with this shaft extension, I really need a 'pusher' of some description. Any ideas are welcome but I don't think a scissor jack will fit in there as there is only about 30mm of room between the shaft extension and the flywheel (inch and a quarter in old money). Here's some pics of progress:

Bottom of the crankcase with oil filter/pump attached.

Oil pump

Piston and con-rod

A few pictures of the shaft, feel free to ask questions if you can't make it out.

I cut/kicked the old rotten wooden trolley off it and had to hacksaw off the mounting bolts (don't worry, they were only cheapo metric things). Then I decided to remove the sump/baseplate. Inside I found the oil pump and removed that. I managed to get the pulley off on Friday when I was supposed to be packing the car for the rally.

Then I undid the big end to remove the piston and con-rod. Of course, I emptied the oil before doing any of this.

Then I could rest the piston on the workmate I am using as a bench and get the gudgeon pin out. Christ only knows how I'm going to get it back in, it is a really tight fit.

I am now stuck on the last flywheel and what I now think is a shaft extension. Like I said, I removed the pulley, it came off relatively easily with a three legged puller but a puller will be useless with this shaft extension, I really need a 'pusher' of some description. Any ideas are welcome but I don't think a scissor jack will fit in there as there is only about 30mm of room between the shaft extension and the flywheel (inch and a quarter in old money). Here's some pics of progress:

Bottom of the crankcase with oil filter/pump attached.

Oil pump

Piston and con-rod

A few pictures of the shaft, feel free to ask questions if you can't make it out.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

The pictures seem to have been trimmed a bit, if you want to see them in their full glory then right click on them and select "view image", then you'll get the full picture.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

How are the big end shells looking???

Any major wear or scarring???

I think you need something like a slide hammer or something like that on that shaft extension. Did you get all the grub-screws etc out???

Any major wear or scarring???

I think you need something like a slide hammer or something like that on that shaft extension. Did you get all the grub-screws etc out???

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Big end shells look fine and there seemed to be no play. The little end looked fine as well although there looks to be no bearing in there at all but I'm sure there is.

The base gasket also came off in one piece, which I think is amazing after all these years!

I was just thinking slide hammer or maybe some wooden wedges (actually they are ideas my air rifle buddies have given me on my shooting forum where they are following my progress ). As far as I can tell there are no grub screws and never were any grub screws, how this shaft extension was holding on is anyone's guess

). As far as I can tell there are no grub screws and never were any grub screws, how this shaft extension was holding on is anyone's guess

The base gasket also came off in one piece, which I think is amazing after all these years!

I was just thinking slide hammer or maybe some wooden wedges (actually they are ideas my air rifle buddies have given me on my shooting forum where they are following my progress

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Ianhw77k wrote:Big end shells look fine

OK, I tell a lie

I am wondering if using some high moly content (MS2) paste on the bearings and bore etc when I put it back together might be a good idea? It should stay there for a while and increase the engine's life expectancy but I'm not sure what effect the oil will have on it, if any at all and I am only talking about a thin smear. I use it in air rifles and it works wonders. What does everyone think?

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

if as you say there is nothing visible holding it in then heating the thicker bit may expand it enough to get the smaller bit out ........... presumably there will be a key in there to provide the drive (i can see a keyway in the shaft) so it will need to come out in a straight line

i am guessing it was made that way to allow a little leeway between the 2 parts while still providing a drive between the 2

i am guessing it was made that way to allow a little leeway between the 2 parts while still providing a drive between the 2

_________________

Lister D............ Lister domestic water pump

Petter A1 .......................Union pillar drill

National F type 1935.............wood planer

argosy pump

Villiers mk 15

hob- Life Member

- Posts : 725

Join date : 2011-06-14

Age : 72

Location : East Suffolk

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I'm wondering if there may well be a tapered key in there Nev, as far as I know that is the only type of key designed to take any load, all the others (parallel and woodruff) are purely designed for location only.

Either way, this does look like a bit of a lash up but it must have worked.

Heat is the direction I was thinking of going in but it will still need some force applied, either with a slide hammer or some hardwood wedges. I'm pretty sure I can see a key in there somewhere, otherwise it would be an engineering miracle

Either way, this does look like a bit of a lash up but it must have worked.

Heat is the direction I was thinking of going in but it will still need some force applied, either with a slide hammer or some hardwood wedges. I'm pretty sure I can see a key in there somewhere, otherwise it would be an engineering miracle

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Even Gib Keys (tapered keys) don't actually take any drive, they simply lock the pulley/wheel/whatever onto the shaft by pulling it tight against it.

It's true though, as Ian said, keys don't actually take any drive, if they did they would very quickly shear off, most are only soft metal anyway, & if a key has sheared off it means something wasn't put together correctly in the first place.

But, as this is the case, it is still possible to see these things operating without a key at all. If that shaft is a really tight fit the key may have been left out, may have fallen out or even rusted away, long ago.

As Neville says, heat is going to be needed I reckon, whatever we've got in there.

It's quite likely that there is a tapered Gib key in there though, it's quite common to cut the ends off them to allow for a pulley or just for safety's sake. Or someone may have used a short one & knocked it in there with a punch (just to be awkward). I doubt they were thinking about you taking it apart in several decades time!

Anyway, never mind hardwood wedges, I think we should get some metal wedges in there. I haven't actually got any, if anyone here knows where I can get some I would be grateful, I've been on the lookout for some metal wedges for ages now, preferably steel but anything would do (well, within reason, not lead or solder or mercury or anything silly like that).

It's true though, as Ian said, keys don't actually take any drive, if they did they would very quickly shear off, most are only soft metal anyway, & if a key has sheared off it means something wasn't put together correctly in the first place.

But, as this is the case, it is still possible to see these things operating without a key at all. If that shaft is a really tight fit the key may have been left out, may have fallen out or even rusted away, long ago.

As Neville says, heat is going to be needed I reckon, whatever we've got in there.

It's quite likely that there is a tapered Gib key in there though, it's quite common to cut the ends off them to allow for a pulley or just for safety's sake. Or someone may have used a short one & knocked it in there with a punch (just to be awkward). I doubt they were thinking about you taking it apart in several decades time!

Anyway, never mind hardwood wedges, I think we should get some metal wedges in there. I haven't actually got any, if anyone here knows where I can get some I would be grateful, I've been on the lookout for some metal wedges for ages now, preferably steel but anything would do (well, within reason, not lead or solder or mercury or anything silly like that).

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Well, wooden wedges don't work and I don't think metal ones will either, they are too unstable. There is that hole in there where you can see the end of the crankshaft, a small metal wedge (maybe even a gib key) could be inserted in there? Either that or I am going to need a slide hammer and some way of attaching it to the shaft extension piece. Any of these ideas will have to be used in conjunction with some heat so the removal of this shaft is going to have to wait until I can find the right tools and some gas for my blowlamp.

After trying the wooden wedges this afternoon and having no luck I decided to turn my attention to the barrel and valves. Both valves are out now, which wasn't easy without a valve spring compressor! Both ports, especially the exhaust port are coked up and the exhaust valve will need grinding in as well as both valves needing a good clean. By the looks of it, the exhaust valve seat has been replaced at some time and the inlet seat looks to be in good condition.

I also started cleaning up the mating faces, removing the strange, fibrous, white gasket material that was between the barrel and block. This stuff was really sticky and a pig to remove! So far the only gasket that we need to make up will be for this face and it looks like an easy one.

I also think we need to remove the exhaust pipe/silencer so I can get into the port. I've started wire brushing around the thread and feeding with WD40 (until I get something better)

No pictures, didn't think it was really worth it.

After trying the wooden wedges this afternoon and having no luck I decided to turn my attention to the barrel and valves. Both valves are out now, which wasn't easy without a valve spring compressor! Both ports, especially the exhaust port are coked up and the exhaust valve will need grinding in as well as both valves needing a good clean. By the looks of it, the exhaust valve seat has been replaced at some time and the inlet seat looks to be in good condition.

I also started cleaning up the mating faces, removing the strange, fibrous, white gasket material that was between the barrel and block. This stuff was really sticky and a pig to remove! So far the only gasket that we need to make up will be for this face and it looks like an easy one.

I also think we need to remove the exhaust pipe/silencer so I can get into the port. I've started wire brushing around the thread and feeding with WD40 (until I get something better)

No pictures, didn't think it was really worth it.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I wonder if one of these might help?

http://www.ebay.co.uk/itm/Morse-Taper-Drift-Key-Set-MT-1-2-3-Drifts-Free-P-P-/140301878506?pt=UK_BOI_Metalworking_Milling_Welding_Metalworking_Supplies_ET&hash=item20aaa4c4ea

http://www.ebay.co.uk/itm/Morse-Taper-Drift-Key-Set-MT-1-2-3-Drifts-Free-P-P-/140301878506?pt=UK_BOI_Metalworking_Milling_Welding_Metalworking_Supplies_ET&hash=item20aaa4c4ea

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Do you want to keep the collar and output shaft or will it be going in the scrap after ?

In that case you could go carfull with the grinder and a cutting disc and score through it on the no crank end does not matter if went through and hit other shaft . Get a arrangement of wedges chisels etc and should come off then . I had to do this with a pulley on my Fowler even with a 20tonne hydraulic puller and lots of heat and soaking did not want to know . Worked fine but go careful as looks a rather small crank and dont want to bend it .

All the best , matt

In that case you could go carfull with the grinder and a cutting disc and score through it on the no crank end does not matter if went through and hit other shaft . Get a arrangement of wedges chisels etc and should come off then . I had to do this with a pulley on my Fowler even with a 20tonne hydraulic puller and lots of heat and soaking did not want to know . Worked fine but go careful as looks a rather small crank and dont want to bend it .

All the best , matt

_________________

Reproduction amanco silencers made , contact me for details

matt

matt86- Admin

- Posts : 5577

Join date : 2011-03-29

Age : 38

Location : swindon/ faringdon

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Ianhw77k wrote:I wonder if one of these might help?

http://www.ebay.co.uk/itm/Morse-Taper-Drift-Key-Set-MT-1-2-3-Drifts-Free-P-P-/140301878506?pt=UK_BOI_Metalworking_Milling_Welding_Metalworking_Supplies_ET&hash=item20aaa4c4ea

seems cheap enough .... give it a go .... have you tried a tapered punch in the hole ?

matt86- Admin

- Posts : 5577

Join date : 2011-03-29

Age : 38

Location : swindon/ faringdon

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

matt86 wrote:

seems cheap enough .... give it a go .... have you tried a tapered punch in the hole ?

I was just about to say I haven't got a tapered punch, then I remembered I bought a whole set of them in February

Having a blonde moment, its been one of those days

Oh, and yes Matt, I would like to keep the extension, at least for now until I can see what is underneath.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Hmmm, Morse taper keys, why didn't I think of those???

They are definitely on my shopping list.

They are definitely on my shopping list.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Something that may help when you rebuild is place the piston into some boiling water to expand the piston before trying to fit the gudgeon pin.

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Cheers Stu, I was thinking of either using my heat gun or my blowtorch when the time comes.stationary stu wrote:Something that may help when you rebuild is place the piston into some boiling water to expand the piston before trying to fit the gudgeon pin.

Stu.

I'm now wondering if my heat gun might be enough to attack that shaft extension? Might be worth a try as I haven't got any gas and I'm nowhere near any shops for a while.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

There's nothing worse then having a problem and not knowing which would be the best way of attack. I have to agree heat does help alot so maybe worth a few days wait till you get some more gas rather then wasting your time or doing damage by trying just brute force.

Stu.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

I got some gas and a cheap set of tapered centre punches today (made some time to pass a large DIY shop). I managed to budge it by about 1mm after bending and hacksawing the largest of the punches and then got it stuck in the hole

I eventually got the punch out and gave up after that, I've got terrible man flu and have been working hard at hedge cutting for the last few days so finding inspiration is a little difficult but at least I got it to move

I am getting a bit worried about all this banging on the shaft as it only has one bearing holding it and the end float seems to have increased but I'm sure it will be fine when its all back together.

I think I'll have to order that set of morse taper drifts, apply a bit more heat and see how it goes. I could probably mount it a bit better in the workmate so I don't put so much strain on that bearing.

In the meantime I will get some better pictures so you can see the whole set-up, the pictures I've taken are a bit too close up.

I eventually got the punch out and gave up after that, I've got terrible man flu and have been working hard at hedge cutting for the last few days so finding inspiration is a little difficult but at least I got it to move

I am getting a bit worried about all this banging on the shaft as it only has one bearing holding it and the end float seems to have increased but I'm sure it will be fine when its all back together.

I think I'll have to order that set of morse taper drifts, apply a bit more heat and see how it goes. I could probably mount it a bit better in the workmate so I don't put so much strain on that bearing.

In the meantime I will get some better pictures so you can see the whole set-up, the pictures I've taken are a bit too close up.

Ianhw77k- A credit to the forum

- Posts : 455

Join date : 2012-07-02

Age : 45

Location : East Sussex

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

It's a good sign if you've managed to move it no matter how small, it should mean the rust seal is broken and you should be able to get some releasing fluid into over the next few days before you try to move it again.

Good luck Ian and keep us up to date on how it goes.

Stu.

Good luck Ian and keep us up to date on how it goes.

Stu.

Guest- Guest

Re: Very old Briggs and Stratton

Re: Very old Briggs and Stratton

Here's how we get a shaft extension off in my workshop! (actually it's my dad's workshop, but that didn't sound quite so good  )....

)....

I'll leave Ian to complete the story for you. Meanwhile I will get a pic of what's left of that shaft extension.

(That's Ian doing the grinding, by the way, I forgot to tell you he's a Smurf, his hands give it away every time, it's a genetic thing, I'm glad to say I'm totally unaffected myself )

)

I'll leave Ian to complete the story for you. Meanwhile I will get a pic of what's left of that shaft extension.

(That's Ian doing the grinding, by the way, I forgot to tell you he's a Smurf, his hands give it away every time, it's a genetic thing, I'm glad to say I'm totally unaffected myself

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Page 2 of 5 •  1, 2, 3, 4, 5

1, 2, 3, 4, 5

Similar topics

Similar topics» 9hp Briggs & Stratton

» Briggs & stratton

» Another Briggs & Stratton

» 2hp Briggs & Stratton

» 1970 Briggs & Stratton 9hp

» Briggs & stratton

» Another Briggs & Stratton

» 2hp Briggs & Stratton

» 1970 Briggs & Stratton 9hp

Page 2 of 5

Permissions in this forum:

You cannot reply to topics in this forum