Just aquired this......

+6

Woodsman

Robotstar5

mattblack

StuartTurnerSteve

maryalice

Garak

10 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Just aquired this......

Just aquired this......

.....Ruston & Hornsby 6PB. 1½hp 700rpm-1000rpm.

Engine number: 163537 was sold on 17.5.1932 to agents Central Machinery Co, Higham Ferrers, Northants.

It needs the flywheel magneto looking at and a fuel tank cap (a forum member has one for me), and a magneto cover.

When I got it home and removed the plug I turned the engine over and it seem to have a tight spot at the bottom of the stroke.

It should make a good restoration project.

Engine number: 163537 was sold on 17.5.1932 to agents Central Machinery Co, Higham Ferrers, Northants.

It needs the flywheel magneto looking at and a fuel tank cap (a forum member has one for me), and a magneto cover.

When I got it home and removed the plug I turned the engine over and it seem to have a tight spot at the bottom of the stroke.

It should make a good restoration project.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

I had a 3hp one for a while, heavy lump but nice engine, I had to make the parts at the bottom of the float bowl, mine had the right angled plug adaptor to keep it away from the oil and the governor loved sticking.

Maryalice

Maryalice

maryalice- Life Member

- Posts : 1310

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Re: Just aquired this......

Re: Just aquired this......

Nice one, bit older than mine! I wonder when Villiers changed from brass to aluminium flywheels.

Wouldn't mind that exhaust!

Wouldn't mind that exhaust!

StuartTurnerSteve- Life Member

- Posts : 534

Join date : 2020-01-02

Re: Just aquired this......

Re: Just aquired this......

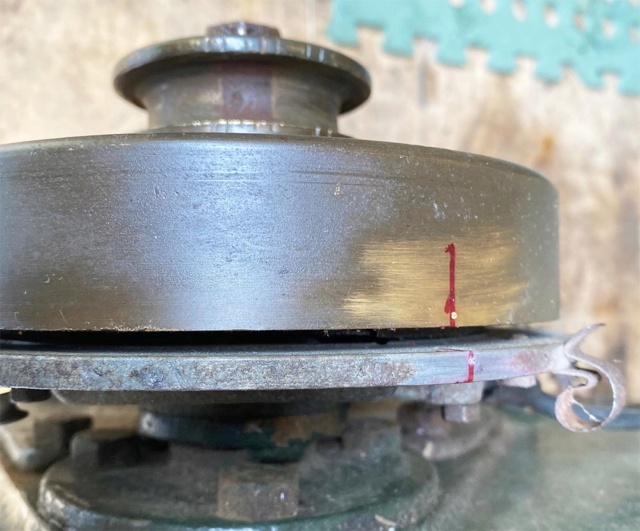

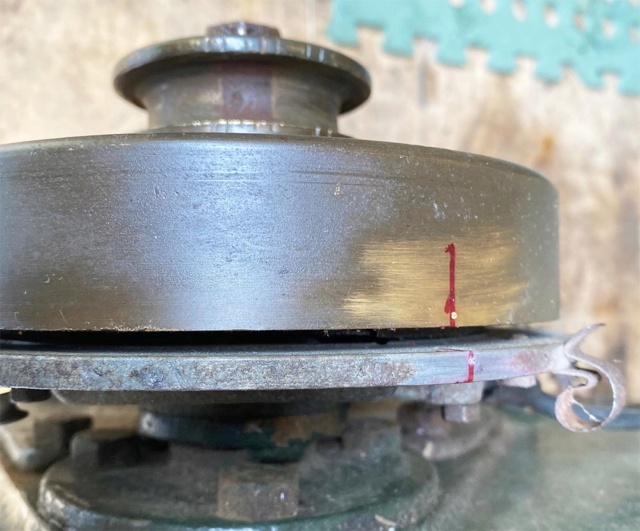

Just hit a snag. The nut on the magneto flywheel is in poor condition (not easily seen in the photo's above) with all of the nice edges rounded off by years of flywheel removal for ignition adjustments ETC.

I was able to crack it off and have managed to move the flywheel ¼" off the taper but I can no longer get a spanner to hold on the flat's. does anyone know of a tool that will lock onto an almost round nut to allow me to continue to undo it. I suppose I may have to weld a bit of bar onto the end of the nut, but although I have a hobbyist arc welder I have never used it.

BTW, the nut is captive and when undone acts as a puller to break the taper on the magneto flywheel, I think the engine has been sitting outside for some time judging by the rust that area.

Ideas on how to proceed would be greatly appreciated.

Thanks

Here's a photo, It's actually worse than it looks in this photo.

I was able to crack it off and have managed to move the flywheel ¼" off the taper but I can no longer get a spanner to hold on the flat's. does anyone know of a tool that will lock onto an almost round nut to allow me to continue to undo it. I suppose I may have to weld a bit of bar onto the end of the nut, but although I have a hobbyist arc welder I have never used it.

BTW, the nut is captive and when undone acts as a puller to break the taper on the magneto flywheel, I think the engine has been sitting outside for some time judging by the rust that area.

Ideas on how to proceed would be greatly appreciated.

Thanks

Here's a photo, It's actually worse than it looks in this photo.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Good luck, mine was a bugger! I had to use a lump hammer to get it to move.

Only thing I could think of would be a set of mole grips if it's past a spanner.

Only thing I could think of would be a set of mole grips if it's past a spanner.

StuartTurnerSteve- Life Member

- Posts : 534

Join date : 2020-01-02

Re: Just aquired this......

Re: Just aquired this......

Aquire a large nut and weld it on, you need to get a new one made anyway.

maryalice- Life Member

- Posts : 1310

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Re: Just aquired this......

Re: Just aquired this......

+1 on the weld a nut on idea.

There are nuts and complete flywheels on ebay, I'm guessing it's a standard Villers flywheel that was used on their own engines so you should be able to match part numbers?

There are nuts and complete flywheels on ebay, I'm guessing it's a standard Villers flywheel that was used on their own engines so you should be able to match part numbers?

_________________

Specialist in precision guesswork.

mattblack- Life Member

- Posts : 889

Join date : 2019-06-21

Location : Leicester, me duck...

Re: Just aquired this......

Re: Just aquired this......

I use a set of Irwin bolt extractors which will grip rounded nuts as well, what is the AF size and I will check if the set covers it.

_________________

Stuart

Robotstar5- Life Member

- Posts : 1110

Join date : 2018-09-25

Re: Just aquired this......

Re: Just aquired this......

Can you unscrew the three screws and get the pulley off? Might be decent metal hidden away underneath.

Last edited by Woodsman on Tue May 31 2022, 14:41; edited 1 time in total (Reason for editing : typo)

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2819

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Just aquired this......

Re: Just aquired this......

Had a bit of time to work on the RH.

No matter how hard I try the magneto flywheel refuses to budge, it has moved away from the housing by about 1\4" but refuses to come any further, I'm reluctant to use brute force and have some Irwin style bolt removers on order. As can be seen the nut is in really poor condition.

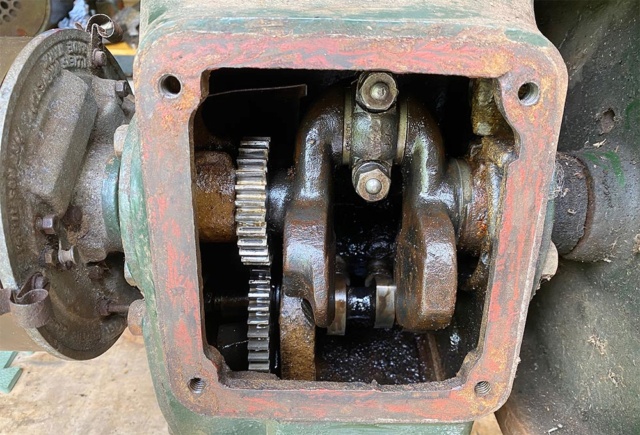

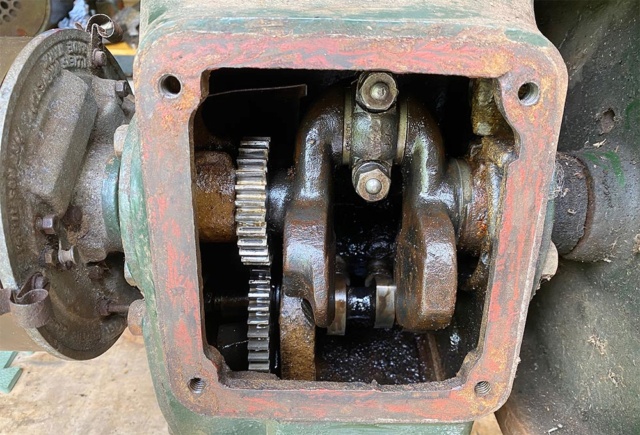

I can't see from a visual inspection why there is a tight spot when the engine is turned at the bottom of the stroke, everything seems OK inside the crankcase.

Upon cleaning the tank of rust I discovered quite a few pin holes at the bottom and as I have had very good results in the past using JB Weld repair putty which is oil and fuel resistant I'm going to use that as I have used it in the past on an Amanco tank with great success.

I am also having difficulty removing the small diameter pulley on the flywheel side of the crank. The retaining grub screws have come out easily but the pulley is stuck fast and I can't get a puller on it so for the moment I have dosed it in penetrating fluid until I can get access to a large set of Stilsons to try to get it to shift.

No matter how hard I try the magneto flywheel refuses to budge, it has moved away from the housing by about 1\4" but refuses to come any further, I'm reluctant to use brute force and have some Irwin style bolt removers on order. As can be seen the nut is in really poor condition.

I can't see from a visual inspection why there is a tight spot when the engine is turned at the bottom of the stroke, everything seems OK inside the crankcase.

Upon cleaning the tank of rust I discovered quite a few pin holes at the bottom and as I have had very good results in the past using JB Weld repair putty which is oil and fuel resistant I'm going to use that as I have used it in the past on an Amanco tank with great success.

I am also having difficulty removing the small diameter pulley on the flywheel side of the crank. The retaining grub screws have come out easily but the pulley is stuck fast and I can't get a puller on it so for the moment I have dosed it in penetrating fluid until I can get access to a large set of Stilsons to try to get it to shift.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Those nuts are really tight if they've not been undone in a while. I had to get someone to hold the main flywheel still while I smack a spanner with a 6lb lump hammer to shift the nut. Head nuts were also tight, bit of tapping back of forward was required.

StuartTurnerSteve- Life Member

- Posts : 534

Join date : 2020-01-02

Re: Just aquired this......

Re: Just aquired this......

You could also try heating the pulley to break the bond between the pulley and the shaft before you put stillsons on it

_________________

blue cat

blue cat- Life Member

- Posts : 1065

Join date : 2013-10-10

Re: Just aquired this......

Re: Just aquired this......

I have today managed to remove the magneto flywheel. I have also remove the backplate from the engine. The components are in poor condition and some will need replacement. The coils secondary winding is open circuit as is the condenser, the points may also have to be replaced along with a new lead-out tower and one of the three clips that holds the rotor cover in place has snapped off.

As in the RH instructions I have placed a couple of steel pieces (two large Allen keys) across the magnet polls to prevent the loss of magnetism.

I have also managed to discover what was causing the tight spot at the bottom of the stroke, one of the iron cores on the backplate had come loose and was binding on the rotor causing the tight spot.

As in the RH instructions I have placed a couple of steel pieces (two large Allen keys) across the magnet polls to prevent the loss of magnetism.

I have also managed to discover what was causing the tight spot at the bottom of the stroke, one of the iron cores on the backplate had come loose and was binding on the rotor causing the tight spot.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Just returned from my summer break and had some time to work on the 6PB. I've repaired the tank and primed. The cylinder head is off as are all of the engine covers. The bore is unmarked and the engine bearings seem to be OK. I had to free off the governor mechanism but now OK. I'm still working to get the belt pulley off so that I can remove the flywheel.

Parcelfarce arrived this afternoon with my vapour blasted and re-furbished magneto. The only original parts are the Aluminium backplate and the laminated iron core pieces, everything else seen is brand new as is the Aluminium rotor cover.

For this engine I have decided to use Craftmaster paint instead of my previous choice of Paragon, I don't think Paragon is very fuel proof.

Re-furbished magneto with its new rotor cover.

Parcelfarce arrived this afternoon with my vapour blasted and re-furbished magneto. The only original parts are the Aluminium backplate and the laminated iron core pieces, everything else seen is brand new as is the Aluminium rotor cover.

For this engine I have decided to use Craftmaster paint instead of my previous choice of Paragon, I don't think Paragon is very fuel proof.

Re-furbished magneto with its new rotor cover.

Last edited by Garak on Wed Jul 06 2022, 16:43; edited 1 time in total (Reason for editing : Added text)

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Got a little further.

Tank repaired, primed and one coat of Craftmaster Ruston Bronze Green, engine covers removed, primed and one top coat. I also made new gaskets for the covers and purched a new copper head gasket.

I had previously managed (after a considerable struggle) to remove the 3" belt pulley which gives me access to the main flywheel gib key, when this is out and the flywheel is removed I can give the entire engine its first coat of new paint then when I have re-installed the covers, carby ETC I can give the whole engine it's second coat of paint before installing the magneto.

Tank repaired, primed and one coat of Craftmaster Ruston Bronze Green, engine covers removed, primed and one top coat. I also made new gaskets for the covers and purched a new copper head gasket.

I had previously managed (after a considerable struggle) to remove the 3" belt pulley which gives me access to the main flywheel gib key, when this is out and the flywheel is removed I can give the entire engine its first coat of new paint then when I have re-installed the covers, carby ETC I can give the whole engine it's second coat of paint before installing the magneto.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Almost finished.

Some lumpy running sorted out by replacing the spark plug with a new 'old stock' Champion 7. Got to get used to adjusting the mixture using the air valve and not a mixture screw. It looks like I missed a tiny pin hole in the fuel tank as some paint is bubbling, should be an easy fix though. Overall I'm quite pleased. I'll post a better video when I take it to a local event.

Some lumpy running sorted out by replacing the spark plug with a new 'old stock' Champion 7. Got to get used to adjusting the mixture using the air valve and not a mixture screw. It looks like I missed a tiny pin hole in the fuel tank as some paint is bubbling, should be an easy fix though. Overall I'm quite pleased. I'll post a better video when I take it to a local event.

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Lovely, sounds pretty good to me!

Alan

Alan

Alanengine- A credit to the forum

- Posts : 461

Join date : 2020-11-21

Re: Just aquired this......

Re: Just aquired this......

Great stuff, it gives the impression that it would happily run forever if you kept topping the fuel up!

_________________

Specialist in precision guesswork.

mattblack- Life Member

- Posts : 889

Join date : 2019-06-21

Location : Leicester, me duck...

Re: Just aquired this......

Re: Just aquired this......

Sound and looks great, impressive turn around time! Mines still looking sorry for itself in my in-laws garage...

Where did you get your Magneto done? Mine seems to have lost spark and I like the result you have had with yours.

Where did you get your Magneto done? Mine seems to have lost spark and I like the result you have had with yours.

StuartTurnerSteve- Life Member

- Posts : 534

Join date : 2020-01-02

Re: Just aquired this......

Re: Just aquired this......

StuartTurnerSteve wrote:

Where did you get your Magneto done? Mine seems to have lost spark and I like the result you have had with yours.

Scroll down to the bottom of this page:

Villiers Parts Magneto

Garak- Life Member

- Posts : 551

Join date : 2017-01-10

Location : North Midlands

Re: Just aquired this......

Re: Just aquired this......

Congratulations on an excellent job.

_________________

Regards Paul

Tha can alus tell a Yorkshireman - but tha can't tell him much.

Woodsman- Admin

- Posts : 2819

Join date : 2014-08-24

Age : 73

Location : God's own county

Re: Just aquired this......

Re: Just aquired this......

Lovely result well done, a very desirable engine

Andywaters- Life Member

- Posts : 609

Join date : 2021-09-15

Age : 66

Re: Just aquired this......

Re: Just aquired this......

Garak wrote:StuartTurnerSteve wrote:

Where did you get your Magneto done? Mine seems to have lost spark and I like the result you have had with yours.

Scroll down to the bottom of this page:

Villiers Parts Magneto

Thanks, doesn't seem to bad considering a coil is £65 on its own.

StuartTurnerSteve- Life Member

- Posts : 534

Join date : 2020-01-02

Re: Just aquired this......

Re: Just aquired this......

Looks and sounds to be a lovely example, well worth your time and effort, excellent result. I don't know why but I have always liked the form of these engines, having a very compact and functional design.

Neil.

Neil.

neil (LE)- A credit to the forum

- Posts : 399

Join date : 2012-03-21

Age : 68

Location : N/W Kent

Re: Just aquired this......

Re: Just aquired this......

Nice engines but I find them the inverse of a Tardis, small but very heavy

Maryalice

Maryalice

maryalice- Life Member

- Posts : 1310

Join date : 2010-01-23

Age : 70

Location : Bedfordshire

Page 1 of 2 • 1, 2

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum