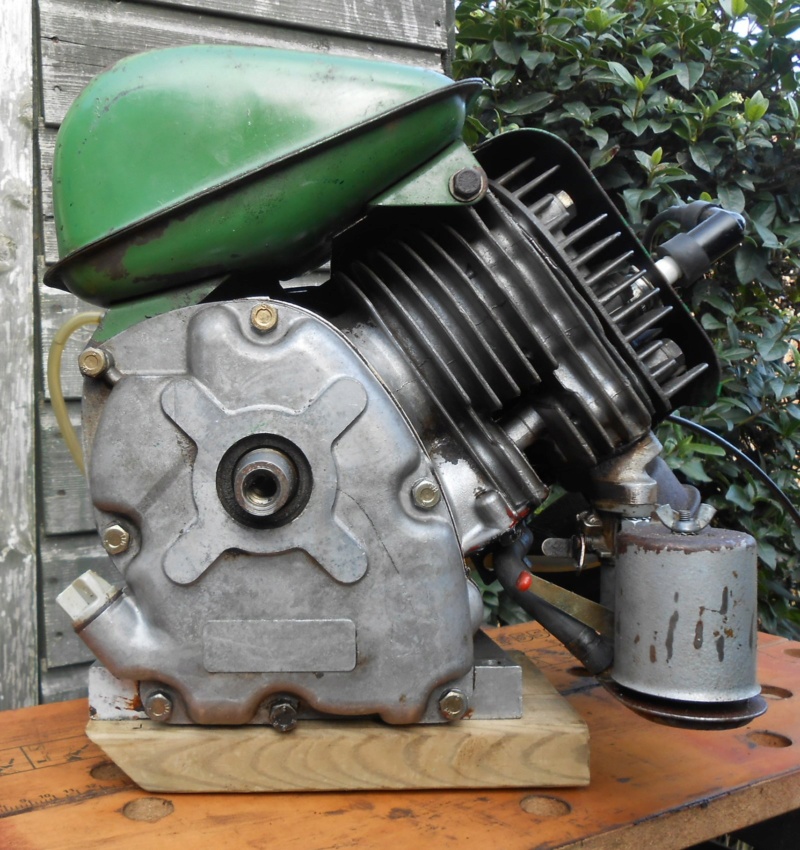

Villiers A15

4 posters

Page 1 of 1

Re: Villiers A15

Re: Villiers A15

Hi Stuart,

Looks a tidy engine what would it originally have driven with that tapered shaft if you know what taper it is ( eg morse)or an other you can easily bore one out if u have a lathe or a mate who has one, it looks as though it may have thread in the end of the shaft, the mags on Villiers have a tapered shaft maybe it is the same!!,i like viiliers they are robust little engines.

Regards,

Keith.

Looks a tidy engine what would it originally have driven with that tapered shaft if you know what taper it is ( eg morse)or an other you can easily bore one out if u have a lathe or a mate who has one, it looks as though it may have thread in the end of the shaft, the mags on Villiers have a tapered shaft maybe it is the same!!,i like viiliers they are robust little engines.

Regards,

Keith.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Re: Villiers A15

Re: Villiers A15

I believe it came off a mower, possibly Ransomes so I need to do a bit of research.

I need to get the measuring gear out to see what the taper is.

Stuart.

I need to get the measuring gear out to see what the taper is.

Stuart.

Robotstar5- Life Member

- Posts : 1084

Join date : 2018-09-25

Re: Villiers A15

Re: Villiers A15

If you can establish what the taper is you could then buy a blank set over the topslide on a lathe and bore out to suit,best of luck if,you do find the taper put it on the forum there will surely be someone else looking for this info.

Keith.

Keith.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

blue cat- Life Member

- Posts : 1041

Join date : 2013-10-10

Re: Villiers A15

Re: Villiers A15

chiefy wrote:If you can establish what the taper is you could then buy a blank set over the topslide on a lathe and bore out to suit,best of luck if,you do find the taper put it on the forum there will surely be someone else looking for this info.

Keith.

Only got the sales brochure drawing to hand at the moment, don't know if it has the dimensions needed as the last time I dealt with engineering drawings was about 40 years ago

Stuart.

Robotstar5- Life Member

- Posts : 1084

Join date : 2018-09-25

Villiers A 15

Villiers A 15

Looks like .750 (or 3/4") in old money is the max width recommended for the pulley width on the taper that would enable you to get a a V belt pulley to enable you to drive off the crankshaft although i do not recognise the taper.Robotstar5 wrote:chiefy wrote:If you can establish what the taper is you could then buy a blank set over the topslide on a lathe and bore out to suit,best of luck if,you do find the taper put it on the forum there will surely be someone else looking for this info.

Keith.

Only got the sales brochure drawing to hand at the moment, don't know if it has the dimensions needed as the last time I dealt with engineering drawings was about 40 years ago

St

uart.

Regards,

Keith.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Re: Villiers A15

Re: Villiers A15

Thought I'd revive the thread, found the correct bit to fit the output shaft locally (thanks @solsteam)

I will now find someone with a lathe and get a groove machined in it to take a car type drive belt.

I had a spare hour yesterday so stripped and cleaned the carb and after screwing a bit of old wood to the base to keep the exhaust clear fired it up....

I will now find someone with a lathe and get a groove machined in it to take a car type drive belt.

I had a spare hour yesterday so stripped and cleaned the carb and after screwing a bit of old wood to the base to keep the exhaust clear fired it up....

_________________

Stuart

Robotstar5- Life Member

- Posts : 1084

Join date : 2018-09-25

Re: Villiers A15

Re: Villiers A15

Would it not be easier to bolt a pulley to that plate?

_________________

Specialist in precision guesswork.

mattblack- Life Member

- Posts : 826

Join date : 2019-06-21

Location : Leicester, me duck...

Re: Villiers A15

Re: Villiers A15

mattblack wrote:Would it not be easier to bolt a pulley to that plate?

It's an option, although my engineering skills are not the best (sparky by trade) so getting it bolted on to run concentric may be fun.

_________________

Stuart

Robotstar5- Life Member

- Posts : 1084

Join date : 2018-09-25

Re: Villiers A15

Re: Villiers A15

Just bolt it to the plate as near concentric as you can then set the plate up to run true in the lathe and machine the bolt on hey presto you have a concentric drive pulley.

Regards,

Chiefy.

Regards,

Chiefy.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Re: Villiers A15

Re: Villiers A15

chiefy wrote:Just bolt it to the plate as near concentric as you can then set the plate up to run true in the lathe and machine the bolt on hey presto you have a concentric drive pulley.

Regards,

Chiefy.

I'm afraid you will have to explain that a bit more, maybe with a drawing if possible.

_________________

Stuart

Robotstar5- Life Member

- Posts : 1084

Join date : 2018-09-25

Re: Villiers A15

Re: Villiers A15

Ok here goes put the flywheel in the lathe independent 4 jaw chuck set the bore of the flywheel to run true this is done with a dti or a dial test indicator when it is true bolt on the lump of metal you are using for a pulley then machine the lump into the type of pulley you require i e flat belt or V groove you then have a pulley running concentric with the flywheel.

Regards,

Chiefy.

Regards,

Chiefy.

chiefy- A credit to the forum

- Posts : 264

Join date : 2013-08-21

Age : 87

Location : near huddersfield

Robotstar5- Life Member

- Posts : 1084

Join date : 2018-09-25

Similar topics

Similar topics» villiers 12/2 hs

» engine number 4 of the VILLIERS WX11 PROJECTS

» Villiers c12

» Villiers F15

» Villiers Mk 20 and Villiers Mk 40 HS

» engine number 4 of the VILLIERS WX11 PROJECTS

» Villiers c12

» Villiers F15

» Villiers Mk 20 and Villiers Mk 40 HS

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum|

|

|