Villiers Century Unit Help

4 posters

Page 1 of 1

Villiers Century Unit Help

Villiers Century Unit Help

Hi,

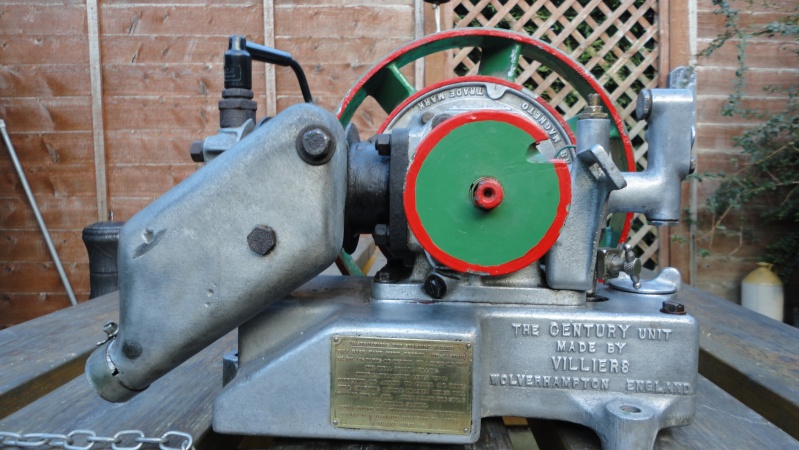

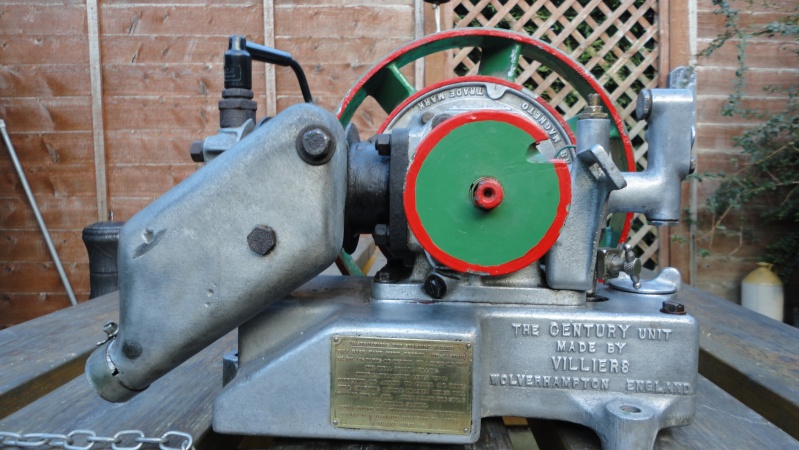

I have recently purchased this Villiers century unit stationary engine, with the hope of cleaning it up and eventually getting it running. I believe this to be a Mk.1 due to the serial number stamped in the top (BCU 215) . I have cleaned the carb through and tested for a spark, which is there faintly, I think a new plug is in order.

Just wondered if anybody had any information that would help getting it started, because at the moment Im clutching at straws trying to get it started.

Any information like:

- Direction of rotation (looking at the flywheel)

- Instruction manuals

- Timing the spark (No woodruff key so cam could be in any position on the crank)

- Suction carb settings (main needle, ECT)

- Spark plug thread (Or fitting plugs)

- Any other general information.

[img] [/img]

[/img]

Any help would be appreciated.

Thanks

Josh

I have recently purchased this Villiers century unit stationary engine, with the hope of cleaning it up and eventually getting it running. I believe this to be a Mk.1 due to the serial number stamped in the top (BCU 215) . I have cleaned the carb through and tested for a spark, which is there faintly, I think a new plug is in order.

Just wondered if anybody had any information that would help getting it started, because at the moment Im clutching at straws trying to get it started.

Any information like:

- Direction of rotation (looking at the flywheel)

- Instruction manuals

- Timing the spark (No woodruff key so cam could be in any position on the crank)

- Suction carb settings (main needle, ECT)

- Spark plug thread (Or fitting plugs)

- Any other general information.

[img]

[/img]

[/img]

Any help would be appreciated.

Thanks

Josh

Last edited by Fletch_971 on Sat Feb 16 2013, 17:10; edited 1 time in total (Reason for editing : Wrong Picture uploaded)

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Fletch_971 wrote:Hi,

I have recently purchased this Villiers century unit stationary engine, with the hope of cleaning it up and eventually getting it running. I believe this to be a Mk.1 due to the serial number stamped in the top (BCU 215) . I have cleaned the carb through and tested for a spark, which is there faintly, I think a new plug is in order.

Just wondered if anybody had any information that would help getting it started, because at the moment Im clutching at straws trying to get it started.

Any information like:

- Direction of rotation (looking at the flywheel)

- Instruction manuals

- Timing the spark (No woodruff key so cam could be in any position on the crank)

- Suction carb settings (main needle, ECT)

- Spark plug thread (Or fitting plugs)

- Any other general information.

[img][/img]

if you look at the flywheel cooling fins they need to spin clockwise from flywheel magneto side,or in a anti clockwise direction from rear pulley with the cut out that also shows to pull rope anti clockwise

the norm for villiers keyless flywheel timing is set the piston to 3/16" before top dead centre turning in a clockwise direction

then rotate the flywheel clockwise direction untill the points start to open then tighten up tight to the crankshaft and watch the engines piston dont move or the flywheel the other way while tightening up

spark plugs

try as many as you can of differnt makes and models as i have oads of villiers petrol ,2 stroke , vapourizing oil and diesels too

but each one will run on a completly different make and/or model to the next ,some wont even spark with the pplug from the other engine and so on

so its trial and error but originally they were suplied with

"PINK coloured " LODGE PLUGS "

kev

Any help would be appreciated.

Thanks

Josh

_________________

" IF YOU DONT DO ANYTHING " "" YOU'LL NEVER MAKES MISTAKES ""

" IF YOU DONT DO ANYTHING " "" YOU'LL NEVER MAKES MISTAKES ""

kevjhnsn- Life Member

- Posts : 3596

Join date : 2011-02-10

Age : 46

Location : south cheshire

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Thanks for your help, never thought about the direction of the cooling fins.

Just the carb now.

Thanks again

Just the carb now.

Thanks again

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Fletch_971 wrote:Thanks for your help, never thought about the direction of the cooling fins.

Just the carb now.

Thanks again

sorry mate that carb i know nothing about but someone on here should though mate fingers crossed for you

kev

_________________

" IF YOU DONT DO ANYTHING " "" YOU'LL NEVER MAKES MISTAKES ""

" IF YOU DONT DO ANYTHING " "" YOU'LL NEVER MAKES MISTAKES ""

kevjhnsn- Life Member

- Posts : 3596

Join date : 2011-02-10

Age : 46

Location : south cheshire

Spark

Spark

Hi,

Do you happen to know what type of thread the spark plug has (imperial,british standard,metric, etc). Iv measured it as 18mm in diameter if that helps any.

Thanks

Do you happen to know what type of thread the spark plug has (imperial,british standard,metric, etc). Iv measured it as 18mm in diameter if that helps any.

Thanks

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Can you not check the thread on the old spark plug?

This might help you find the correct thread.

http://www.baconsdozen.co.uk/tools/conversion%20charts.htm

Stu.

This might help you find the correct thread.

http://www.baconsdozen.co.uk/tools/conversion%20charts.htm

Stu.

Guest- Guest

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

nice bit of local history for me - the villers site is only a few mile away. my mate used to have a workshop in one of the buildings.

steve w- Life Member

- Posts : 503

Join date : 2012-09-15

Age : 52

Location : Nr Wolverhampton

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Spark plug will be a standard 18mm, available all over the place (just make sure no one sells you a taper seat plug, yours will need a washer).

What a lovely little engine, very much like the Mar-Vil units. I'm sure the early, all iron, ones of these are what Tarpen based their generating set engines on back in the 30's. I've always liked these little Villiers units, I've even thought about making a replica one from an Atco lawnmower Villiers Midget engine.

Your spark problems could well be magneto related, you might want to take a test meter to your coil. If you have a meter, set it to an ohms reading (continuity) & test between the spark plug terminal & a good earth. I'm not entirely sure but I think it should be around 5000 ohms (5 Kohm). If the reading is suspect it could be the HT lead at fault, or the terminal from coil to lead (these should not be soldered as it can damage the coil). If I recall it should be some kind of push fit from coil to lead.

Unfortunately the magneto coils on these are notorious for corrosion problems. Hopefully yours will be fine.

Cracking pictures, keep us posted.

What a lovely little engine, very much like the Mar-Vil units. I'm sure the early, all iron, ones of these are what Tarpen based their generating set engines on back in the 30's. I've always liked these little Villiers units, I've even thought about making a replica one from an Atco lawnmower Villiers Midget engine.

Your spark problems could well be magneto related, you might want to take a test meter to your coil. If you have a meter, set it to an ohms reading (continuity) & test between the spark plug terminal & a good earth. I'm not entirely sure but I think it should be around 5000 ohms (5 Kohm). If the reading is suspect it could be the HT lead at fault, or the terminal from coil to lead (these should not be soldered as it can damage the coil). If I recall it should be some kind of push fit from coil to lead.

Unfortunately the magneto coils on these are notorious for corrosion problems. Hopefully yours will be fine.

Cracking pictures, keep us posted.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

I see your plug is an old detachable type. Personally I would recommend one of these over any modern plug. You might want to test between the terminal & the centre electrode though. I have refurbished quite a few of these plugs recently. Out of the last 7 or 8 Champion detachable plugs I have refurbed at least 6 or 7 of them had a corroded connection between the terminal & the electrode, which showed several megOhms resistance, some showed a complete open circuit. The trouble is they corrode inside, at the very top of the plug. They can be repaired, I recently formulated a way of doing it & will be writing a small thread about it soon.

Just as a note, it's worth testing all spark plugs, new & old, in this manner, I've had brand new plugs with broken electrodes & other faults inside the plug. Any high resistance or open circuit inside the plug will put a huge extra strain on the magneto coil of an engine (any engine) & could result in a burned out coil.

Also, what's the gap on your plug? It shouldn't be over .025" on these. If it's on it's original coil you might even want to close the gap down a little. I gap all mine to .017", it gives the mag an easier time & results in a better spark under compression.

(Generally flywheel mags will take a maximum .025" gap, whereas normal mags shouldn't be over .020". I gap mine at .017" as the gap will increase over time with wear & to make my magneto's life easier. A re-wound magneto, with modern materials & vacuum encapsulation methods will take a larger gap, usually .025").

Just as a note, it's worth testing all spark plugs, new & old, in this manner, I've had brand new plugs with broken electrodes & other faults inside the plug. Any high resistance or open circuit inside the plug will put a huge extra strain on the magneto coil of an engine (any engine) & could result in a burned out coil.

Also, what's the gap on your plug? It shouldn't be over .025" on these. If it's on it's original coil you might even want to close the gap down a little. I gap all mine to .017", it gives the mag an easier time & results in a better spark under compression.

(Generally flywheel mags will take a maximum .025" gap, whereas normal mags shouldn't be over .020". I gap mine at .017" as the gap will increase over time with wear & to make my magneto's life easier. A re-wound magneto, with modern materials & vacuum encapsulation methods will take a larger gap, usually .025").

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Thanks for all your help, il be ordering a new plug shortly - from what Kev put earlier in the thread I believe its got its original plug in from the thirties (Pink lodge) and has seen better days. The plug thats in I believe is a multipoint plug with three points pointing towards the electrode, not desimilar from a modern performance multipoint plug, therefore i cant change the gap as easy on this type. Iv had this engine firing about four times then dying again so I think now its a case of narrowing down what is going wrong, like you said I think the ignition circuit will be a good place to start. The magneto inside is the original with a 'Villiers England' sticker on the side, hopefully its still up to the job. I'll see what I can do

Thanks

Josh

Thanks

Josh

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Yeah, the pink Lodge plugs give the same trouble as the Champion ones, but I've never managed to successfully repair the Lodge ones.

Any old plug will do though, doesn't have to be a multi point.

Keep us informed on how you get on.

Any old plug will do though, doesn't have to be a multi point.

Keep us informed on how you get on.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Just bought a Champion D16, il give it a go when it comes and keep you informed

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Unfortunatly these old Villiers ignition systems were never the best and a lot of engines have been scrapped because of it. Here's a link to a Villiers dealer that stocks a good few spares, if you ask for George he's the man with the knowledge. Thing is parts ain't that cheap so you might have to dig deeper then you'd expect.

http://www.villiersparts.co.uk/

Stu.

http://www.villiersparts.co.uk/

Stu.

Guest- Guest

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Yeah, that's right. A lot of people go down the route of a car type (or old motorcycle type) ignition coil & a small battery wired to the points, but we know of a different way here on this forum.

I would say test that coil first, the older ones were better built than the later ones, but obviously they are older, which goes against them. If you test it & find problems then come back to us & we'll go through the options.

I would say test that coil first, the older ones were better built than the later ones, but obviously they are older, which goes against them. If you test it & find problems then come back to us & we'll go through the options.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

I had a go at testing the coil and lead earlier - from the plug terminal to earth on the engine I get no reading, I then tested just the HT lead with cap (KLG Suppressed cap) and circuit was there with around 1600ohm resistance (I assume the resistance is down to the suppressor). So I then tried across the coil

(From earth to HT lead connection) but I couldn't get any reading??????

Is this good,bad or am I doing something wrong?

(From earth to HT lead connection) but I couldn't get any reading??????

Is this good,bad or am I doing something wrong?

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Sounds like the coil may have had it. Also, you shouldn't really use suppressor caps with magnetos.

Do you know what your meter goes up to in Ohms? The best machine to test these things is an insulation resistance meter, otherwise known as a Megger (a brand name coined by the AVO test meter company).

The thing is, a coil with an open circuit can still produce a spark. What happens is damp gets into the windings & starts to corrode the copper. The wire used on the HT side of the coil is thinner than a human hair (the ones on your head), so it doesn't take much corrosion to rot through it. There are also thousands of turns in this coil as well. What will happen is a small break in the coil will still allow the electricity to jump across, but this will cause it to make the gap bigger over time, until you lose the spark completely.

As this damp damage usually starts from the outer most parts of the coil, sometimes you can remove the outer covering from the coil & remove a few layers of the thin wire, working inwards to the middle where less corrosion will have taken place. But there's only so far you can go with this before you don't have enough turns left to produce a spark. Also, this wire is so thin it's very difficult to find a good end, then solder it onto something stronger, then insulate it properly & wrap it all up again with a decent terminal on the outside for the HT lead. All this needs to be done without breaking the fragile thin copper wire.

If you do try this then bear in mind magneto coils are wound in layers. Each layer of winds in the coil is separated by a layer of impregnated paper.

So, you could try to re-test the coil, see if there is any life left in it (sorry to say these coils are notorious for this), but if you need a new one then be wary of cheap imported coils. Another forum member has restored a couple of old Villiers mower engines (now stationary engines, & very nice job he did too). I think he bought a cheap coil, but had to send the mag off to a proper company to have it put right in the end. It's the old adage I'm afraid, "Buy cheap, buy twice".

It may be worth asking a magneto specialist for a price to re-wind your coil. I have a very good mag bloke down my way, who is happy to ship stuff (he uses a special vacuum encapsulation technique which I know many of them don't, this ensures the entire coil is sealed for life from moisture). I could ask him for a quote if necessary, as I'm not sure how available these earlier coils are.

Anyway, don't give up yet, it may just require different testing. Have a look at your meter, or show us what it looks like.

Fingers crossed for you.

Do you know what your meter goes up to in Ohms? The best machine to test these things is an insulation resistance meter, otherwise known as a Megger (a brand name coined by the AVO test meter company).

The thing is, a coil with an open circuit can still produce a spark. What happens is damp gets into the windings & starts to corrode the copper. The wire used on the HT side of the coil is thinner than a human hair (the ones on your head), so it doesn't take much corrosion to rot through it. There are also thousands of turns in this coil as well. What will happen is a small break in the coil will still allow the electricity to jump across, but this will cause it to make the gap bigger over time, until you lose the spark completely.

As this damp damage usually starts from the outer most parts of the coil, sometimes you can remove the outer covering from the coil & remove a few layers of the thin wire, working inwards to the middle where less corrosion will have taken place. But there's only so far you can go with this before you don't have enough turns left to produce a spark. Also, this wire is so thin it's very difficult to find a good end, then solder it onto something stronger, then insulate it properly & wrap it all up again with a decent terminal on the outside for the HT lead. All this needs to be done without breaking the fragile thin copper wire.

If you do try this then bear in mind magneto coils are wound in layers. Each layer of winds in the coil is separated by a layer of impregnated paper.

So, you could try to re-test the coil, see if there is any life left in it (sorry to say these coils are notorious for this), but if you need a new one then be wary of cheap imported coils. Another forum member has restored a couple of old Villiers mower engines (now stationary engines, & very nice job he did too). I think he bought a cheap coil, but had to send the mag off to a proper company to have it put right in the end. It's the old adage I'm afraid, "Buy cheap, buy twice".

It may be worth asking a magneto specialist for a price to re-wind your coil. I have a very good mag bloke down my way, who is happy to ship stuff (he uses a special vacuum encapsulation technique which I know many of them don't, this ensures the entire coil is sealed for life from moisture). I could ask him for a quote if necessary, as I'm not sure how available these earlier coils are.

Anyway, don't give up yet, it may just require different testing. Have a look at your meter, or show us what it looks like.

Fingers crossed for you.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

If the coil has expired, & a new coil or re-wind is out of your price range, there are alternatives. I did a thread, not so long ago, on this very forum called "More Magneto Experiments" (I think). If you could hide a small motorcycle canister type coil somewhere on or near the engine, then there's no reason why it shouldn't be a reliable runner again. You could also go down the battery & coil route, but involving batteries can be a pain, as they need charging.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

I don't really know what im doing with electronics, more of a mechanical guy. Here's the meter iv been using:[img] [/img]

[/img]

[/img]

[/img]

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Try testing for resistance through the coil on all ohms settings (you probably already did this). You might come up with something.

Be aware though, that at the higher Mohm ratings it will read a circuit through the skin on your body (if you are touching the test lead terminals, but it won't hurt, you won't even feel it on these meters), & possibly through any dampness on the coil, this will result in an unsteady reading.

If it's had it you'll have to think over the options. I can talk you through setting it up to run off a car or bike coil with or without a battery. & don't worry, I keep all my instructions in easy, non electrical, jargon.

P.S. you should really get a reading at the 20 K setting.

Be aware though, that at the higher Mohm ratings it will read a circuit through the skin on your body (if you are touching the test lead terminals, but it won't hurt, you won't even feel it on these meters), & possibly through any dampness on the coil, this will result in an unsteady reading.

If it's had it you'll have to think over the options. I can talk you through setting it up to run off a car or bike coil with or without a battery. & don't worry, I keep all my instructions in easy, non electrical, jargon.

P.S. you should really get a reading at the 20 K setting.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Iv had another go with the meter, I finally got a reading of around 16.5 on the 20M setting it kept fluctuating. Is this right? . It may be the meter iv had some problems with it in the past. Iv got another problem to combat now though, iv found a hairline crack in the carb casting that seems to be sucking a little, iv tried filling it with a little bit of chemical metal,hopefully that will do the trick, i'll soon see.

Fletch_971- I really need to post more

- Posts : 8

Join date : 2013-02-16

Re: Villiers Century Unit Help

Re: Villiers Century Unit Help

Chemical metal is good stuff, but like welding it needs a nice clean, dry surface to adhere to. I've had lots of success with various different types, but I usually use a Dremmel-type machine, with various different bits, to prepare the surface. I'm sure it'll be fine.

It sounds to me like your coil has expired. The HT part of the coil has probably succumbed to moisture over the years. If you get a spark from it then great, & by all means use it for as long as you can, but be prepared that one day, sooner or later, you will need to look into replacement or alternatives (I will ask my local man what he would be likely to charge for a Villiers coil re-wind. I expect there are equal services all over the country, but he's quite well known & respected & I know not all of them use the same vacuum encapsulation techniques, especially as he built his own equipment, so his technique is unique to him, but a similar technique would be easy enough for other specialists to set up, just not all of them can be bothered). You may well want to contact that Villiers spares place that someone linked to earlier in the thread (I think they're quite pricey though, but mag coils aren't cheap whichever way you go about it. It'll probably be best part of £60 at the very cheapest)

Anyway, see how you get on with new lead (were you going to replace the HT lead? Can't remember), different plug terminal & repaired carb.

It sounds to me like your coil has expired. The HT part of the coil has probably succumbed to moisture over the years. If you get a spark from it then great, & by all means use it for as long as you can, but be prepared that one day, sooner or later, you will need to look into replacement or alternatives (I will ask my local man what he would be likely to charge for a Villiers coil re-wind. I expect there are equal services all over the country, but he's quite well known & respected & I know not all of them use the same vacuum encapsulation techniques, especially as he built his own equipment, so his technique is unique to him, but a similar technique would be easy enough for other specialists to set up, just not all of them can be bothered). You may well want to contact that Villiers spares place that someone linked to earlier in the thread (I think they're quite pricey though, but mag coils aren't cheap whichever way you go about it. It'll probably be best part of £60 at the very cheapest)

Anyway, see how you get on with new lead (were you going to replace the HT lead? Can't remember), different plug terminal & repaired carb.

_________________

The "F" key is dying on my computer, please remember this when reading my posts, I'm trying to avoid using it.

The name's Matt, but call me Nutts if you like, there's already enough Matt's about.

nutgone- Life Member

- Posts : 2356

Join date : 2012-07-04

Age : 45

Location : East Sussex

Similar topics

Similar topics» First testrun in the sun Villiers - Benco milking unit

» Another Milking Unit

» jap 2a charging unit.

» Bsa power unit recoil starter

» My BSA power unit 320cc

» Another Milking Unit

» jap 2a charging unit.

» Bsa power unit recoil starter

» My BSA power unit 320cc

Page 1 of 1

Permissions in this forum:

You cannot reply to topics in this forum